Adding a turbo to a non turbo car.

"You can't just 'bolt on' a turbo, it takes careful planning"

In this article we are going to discuss an often raised topic, that of adding a turbo to a naturally aspirated (NA or NASP) engine. People often ask me if you can add a turbo to a non turbo engine, and if it is easy to fit a turbo in your car. Is it even possible to install a turbo on any car?

Turbo conversions and turboing a non turbo car are great ways to add lots of extra power so le't s break this down and open up a world of tuning possibilities.

Our Guide: How to turbo a car and turbo conversion.

The idea of doubling your NASP (NAturally ASpirated or NA) engines power with one "simple turbo upgrade" is certainly appealing. What will a turbo conversion project involve? Common problems after a cars are turbocharged? How do you add a turbo safely to a car?

Forced induction is where highly compressed air is fed into the engine. We would typically use a Supercharger or Turbo to do this.

More air means you can burn more fuel, and by forcing in this compressed air you theoretically increase the cars ability to burn fuel.

Contrary to popular belief this is certainly not a straightforward bolt on part. As you will discover from this article there's lots of additional things needed to make it work.

Adding a turbo or supercharger is a fairly complex modification and one which regularly comes up in our forums so we'll cover the basics of adding a turbo upgrade in this article.

Please watch our video feature on adding a turbo to your car

Modern technology uses ceramic bearings and variable turbine geometry to maximize power and torque.

Why add forced induction?

The basic reason for forced induction (turbo or supercharger) is not to increase the engine's compression or the maximum pressure in each cylinder.

Actually, the primary reason is increasing the engine's volumetric efficiency (the efficiency of the engine at drawing in air and converting this to power by adding fuel and burning it).

In video games like GranTurismo and Forza, we just tick a box to add a turbo. Within seconds our car's fully turbocharged with lots more power. In the real world, things are very different.

What does the turbo do?

The turbo spins faster as the exhaust gases flow faster, compressing more air.

Due to the high temperatures and speeds of a turbo, oil supply is critical. According to our testing at TorqueCars, ball bearings outperform thrust bearings and are the preferred choice for turbo upgrades.

Put a turbo on an engine with an 10:1 compression ratio and watch it explode!

Higher compression engines use direct injection. This is where fuel is fed into the cylinder at the last moment. This helps us avoid premature ignition issues. DI is installed in many modern turbo petrol engines, a technology they borrow from the diesel.

You could also use water injection to dampen the intake charge and retard the timing, but you are starting to get into rocket science territory here, and if you don't know what you are doing I guarantee you will run into problems.

Please watch our video which explains turbos and all you need to know about them. Be sure to keep up with our latest YouTube content and subscribe.

There are a lot of considerations to make when adding a turbo to your NA (naturally aspirated) engine. But one of the keys of car tuning is burning more fuel, and this requires more air.

To improve airflow the intake air must be forced into the engine. This creates the popularity of turbocharger conversions.

So let's see what a turbo conversion mod involves. I will pass on some of the tips I've picked up along the way so you don't end up making the common mistakes.

How to Turbo a Car.

Guide and the essential things to take into account when adding a turbo to a non turbo car (NASP or naturally aspirated engine).

Guide to installing a turbo on a non turbo car.

- Choose an appropriate turbo, generally, you are better off with a low boost turbo that can spool up quickly.

- Make sure you have enough fuel, this will mean upgrading injectors and the fuel pump

- Get an Intercooler, this will help take the intake temps back down after the turbo FMIC's are best

- The exhaust header/manifold and intake piping need to be revised. Good kits are designed to bolt on and have all of the components you need.

- Lowering the engine's compression ratio is required, although some cars will allow a modest level of boost on stock internals. Detonation is your big enemy here.

- Mapping is essential and if this isn't done you risk serious damage. In some cases, an aftermarket ECU is better than trying to modify your current ECU map. Ideally, set up on a rolling road.

- The turbo will need a supply of fresh oil and the manufacturer's recommended grade may not be sufficient for your turbocharged engine.

- Make sure the engine is strong enough, forged crankshaft, conrods, and pistons are a good idea but the quality and suitability will vary according to your needs. (This is a good way to lower the compression ratio.)

If you are thinking of adding a turbo to your car we suggest you join our friendly forum and get some specific tips and advice for your car model.

The Intercooler On Turbo Conversions

What is an intercooler and what does it do?

An intercooler is effectively a radiator that permits the intake air charge to cool before it gets into the engine.

You would ideally mount an intercooler in front of the radiator so that it benefits from all that nice cold air hitting it.

Fit the intercooler after the air intake filter and after the turbo or supercharger. This is where most of the heat is added.

Most cars have front mounted intercoolers which sit in front of the radiator and as a result they tend to offer superior air cooling over top mounted intercoolers.

You need to take into account the fact that the air reaching the radiator is reduced. So you may in extreme cases need to uprate your cars radiator to maintain low on track temperatures.

Power benefits from an intercooler

One of the mods that eliminates a restriction is the addition of an intercooler. It aims to improve the engine's capacity to draw in air effectively and maintain a high level of cooling for extended periods of time.

5 to 10 percent greater power and longer heat soak resistance are big plus points. This can only be gained with a well-designed intercooler.

The advantages of installing an intercooler on your vehicle is explained in this video. Subscribe to our new YouTube channel and show your support for us.

Front mounted or top mounted?

Top mounted intercoolers

- Top-mounted intercoolers provide the advantage of a shorter, lighter route from the compressor to the engine.

- As hot air rises from the engine compartment, there will be less cooling, resulting in faster warming.

Front mounted intercoolers

- It's easy to install since most OEM intercoolers are located on either the front or side of the engine compartment, and it provides the optimum cooling because it faces the air entering the engine.

- Inconvenience of a longer intake hose from compressor to engine; heavier vehicle.

Some cars come equipped with top-mounted intercoolers that draw air in via the bonnet. This might, cause the car to be affected with warm air from the engine compartment when it is stationary.

Because the air is warmer, you can burn less gasoline, which is better for your wallet because you don't want to be running big power levels while stuck in traffic.

As an example of a vehicle with an intercooler installed on top, consider the Subaru Impreza. A top-mounted intercooler provides a far shorter air flow path into the engine, but it will need an air scoop on the top to channel air through it, which might result in drag.

All turbocharged vehicles will benefit from an intercooler, and OEM intercoolers can be improved. Your engine needs as much air as possible sucked in via the intercooler core, therefore if it is obstructed, you will lose power.

Those who say that all intercoolers reduce airflow are wrong; the advantages of installing a high-quality one outweigh the little loss of airflow that comes with a well-designed intercooler.

Each 100 horsepower requires 3 litres of intercooler capacity, on the average. It's a crude rule of thumb, but it appears to work for most vehicles with 150-400bhp!

When it comes to intercoolers, selecting the right size for the application is critical since a huge intercooler might impede airflow (this is something which can be discussed in more detail in our forum.) It's not always preferable to go bigger!

Why fit a turbocharger to your engine?

When a naturally aspirated engine sucks air in, it can only draw so much in before the intake valve closes and seals the cylinder.

The average Naturally Aspirated "NASP" engine will only pull in around 60% of its potential volume, so as a result is only 60% volumetrically efficient.

This is why we don't often see NASP cars producing more than 100bhp per liter - props go to Honda for reaching this level though, but we'll discuss that in another article.

The more highly tuned an engine is, the more efficient it will be.

A typical TorqueCars member will have already spent much time and effort tuning their NA (naturally aspirated) engines but will still struggle to get anything approaching 85% efficiency when using Natural Aspiration.

The best way to increase power is to force more air and correspondingly more fuel into the cylinders (forced induction) thus filling them more.

The average forced induction engine runs from 110% to 150% volumetric efficiency (the incoming air is compressed).

Here are some examples of this to help provide context on the benefits of adding a turbo. A 2 liter NASP motor will use effectively around 1200-1300cc of its capacity and will typically produce up to an optimum 200bhp (based on 100bhp per 1000cc).

A turbocharged or supercharged 2.0 liter engine will use much more of it's capacity, producing more power as it is now able to burn more fuel. (This gives a turbo engine an optimum power figure far in excess of 100bhp per cylinder, some OEM 2.0 engines are pushing out 300bhp!)

Take an extreme example of a turbocharged 1.6 engine in early Formula 1 motorsport that produces almost 1500 bhp.

We frequently see tuned 2.0 litre turbo cars hitting 600bhp and more with relative ease providing daily use whilst maintaining reliability. The key is in having a strong block and components to work from.

Benefits of adding a turbo to your engine

- The more boost you run, the more efficient the engine, hence we have 1.4 litre turbo engines producing as much power as large V6's.

- Having a small but powerful engine, gives you a weight advantage too, improving handling and making the power hike even more impressive when driving the car.

- But the main benefit from increasing boost is to increase the final compression ratio and get a better bang from an increased air/fuel charge mix in your cylinders (the actual engines compression ratio stays the same but as there is more air coming into the engine it will become more compressed).

- If you increase the amount of air/fuel in the cylinders, then as a result you will increase the compression, which could be too much. In order to keep the final running compression the same, the initial compression (without boost) has to be dropped to compensate.

- More air will enable more oxygen to be available for burning and with the addition of additional fuel, the engine will release more power.

- Turbocharging is the best way to increase the efficiency of an engine.

- When adding a turbo to an engine that was not originally designed for a turbo there are some major complications to take into account.

How a turbo works

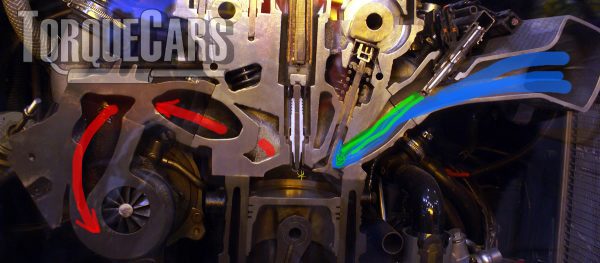

In the illustration below the exhaust gases in RED spin the turbo which sucks in cold air shown in blue, that is mixed with fuel shown in green in this port injection engine and then the pressurized mixture is combusted in the cylinder.

We now have twin scroll turbos which split the exhaust gas flow into two channel from alternative cylinders, this aids a spool up and allows the turbo to spin faster at the top end.

The pictures below show the intenal view of a standard turbo compared to a twin scroll turbo.

In a twin scroll turbo the turbine blades are generally shaped to catch the exhaust flow effectively.

See our guides and articles on Turbos which explain the many options from hybrids and twinscroll turbos.

ECU Mapping for a turbo conversion

Make sure the fuel delivery matches the new quantities of air being pushed into the engine is a top priority, and this will also require adjustment to the spark advance.

After you've added a turbo this has moved things far beyond the expectations of your OEM ECU. So what can we do about this?

To get the greatest power out of your turbo conversion, you'd need to alter the timing and fuelling. Fuel flow and spark timing advance must be finely tuned with an electronic ignition system.

Only in a narrow RPM range did you get near-perfect spark timing. Using a table, the ignition program was able to read the predetermined timing from a complete list of variables.

Precision control of the ignition timing is now achievable thanks to air temperature, engine speed, and load as well as the control over turbo/wastegate control and fuel delivery rates.

Control over fueling and power output will be finely tuned, a must with these latest Turbo chargers and injector technologies. Engine and engine technology have advanced to new heights as a result of the manufacturers' focus on emissions compliance.

Beware of power spikes - see the red line in the diagram below, the green shows a good stead power increase following a profile similar to the stock engine. Power spikes cause wheelspin and are prone to stress engine and turbocharger components.

Most turbos come with airflow maps that can be used to calculate the fuel requirements.

We have a video that explains ECU mapping in more detail.

Aftermarket ECU's - good for turbo upgrade projects

It helps you to get more out of your vehicle than the OEM ECU. Stock ECUs are typically limited.

Instead of focusing on peak performance, automakers usually prioritize the life of various vehicle components rather than following international standards.

Everywhere you look, you'll find aftermarket ECUs for certain vehicle models and uses. They help cars operate better, pass pollution tests and save fuel. An Aftermarket ECU Is Better.

Factory-installed ECUs are built to last instead of for optimum performance. In many cases, the OEM ECUs cannot be remapped, especially in Japanese car models.

Because aftermarket ECUs allow interested parties to increase their vehicle's performance to new heights, they are a valuable investment.

How Does an aftermarket ECU Work?

Every ECU works on the same premise. Input sensors such as engine load, intake temperature, and RPMs are analyzed to make judgments. Also, aftermarket ECUs are programmed to perform certain functions.

The ideal setting for optimizing fuel usage and spark advance is determined by an aftermarket ECU.

The latest trend we see are manufacturers using small capacity engines with turbochargers fitted, and we see a modern 1.4 turbo putting out as much power as an early 2.0 turbo or 3.0 NA (naturally aspirated) engine, with much better fuel economy and it weighs lot less.

Problems when fitting an aftermarket turbocharger.

Pre-ignition or knock - this is where the fuel ignites under pressure before the spark happens.

This will cause a piston to move in the opposite direction if it has not reached the top dead center and will have disastrous consequences for the engine.

Avoiding preignition and detonation in turbo conversions

To avoid detonation (premature ignition) you will need to lower the compression ratio of the engine, and/or restrict the turbo to a lower boost threshold.

(Low compression engines fitted with a turbo will also avoid some of the turbo lag problems inherent in most turbo applications.)

The best turbos to add to a non turbo NASP (Naturally aspirated) engine are small units with low boost levels. Remote turbo kits are gaining popularity thanks to the low boost they provide and not needing space in the engine bay.

Another option you have is to fit a water injection kit to dampen the air charge and prevent detonation.

To lower the compression you can go with a re-bore and fit lower compression pistons, you can add a stroker kit to alter the compression ratio by adjusting the compression stroke length.

For minor adjustments, you could get a larger head and thicker head gasket thus increasing the combustion chamber volume thereby reducing the compression ratio.

You need to aim for around a 7:1 compression ratio if you are adding a turbo, anything above 9:1 and you will have problems. Modern direct injection engines run much higher compression ratios.

Turbo conversions and fuelling

In all cases, you should use the highest octane fuel that you can find as the higher the octane the more resistant the fuel is to engine knock.

With the right fuelling though we have seen people running 25psi of boost on a 10:1 compression ratio but we should add that the aftermarket ECU and fuelling mods were of a very high specification on this application.

If you can reduce the boost pressure to 5-7psi (as opposed to 25-35psi), and use the higher octane fuels available (e.g. Shell Optimax) you should be able to run a turbo on a standard engine with around the 9:1 compression ratio. For information on Octane and its effect on engine knock read our octane article.

Direct injection was pioneered on Diesel engines. It is now used on petrol engines. Because the fuel is injected later into the intake charge it reduces the temperature of the charge and this helps to resist premature ignition.

This is why FSi and Di turbo engines can run very high compression ratios.

Further engine mods to aid reliability and power after turbo conversion

When adding a turbo, for maximum performance gains, you should also get the head flowed, increase the port size, fit bigger valves and go with a larger exhaust header and system as there will be a much larger volume of air flowing through the engine.

Fitting an adjustable boost controller will allow you to experiment on a rolling road while attached to diagnostic equipment to find the optimum boost pressure and timing advance.

Particular attention is required to the fuelling as we are getting much more air into the engine. More air requires more fuel or you risk the danger of burning too lean.

You also want to avoid over fuelling when the boost from the turbo drops as this can destroy the engine.

On most aftermarket turbo applications it is unlikely that the car's existing fuel delivery system will be able to deliver sufficient fuel so you will need to uprate the fuel pressure with a new pump and fuel pressure regulator, the injectors will also need uprating.

The car computer will also need to take into account the new fuelling requirements of a turbo, especially with regard to throttle position and wastegate control and rapidly changing fuel requirements between on and off boost conditions.

The air intake will also require upgrading, as few OEM air intakes can cope with the air requirements of a 40% power hike.

We strongly recommend a good aftermarket ECU to allow you to create a custom map for your new turbocharged engine.

Most kits contain only the necessary parts to physically get the turbo onto the engine such as an exhaust header and the necessary intake plumbing to the air filter.

How long does a turbo conversion take?

Turbos are expensive but will add the most power for your money. You should allow about 40 hours for fitting. You really do need to know what you are doing. Ideally you'll have the ability to create a custom ECU map.

Generally speaking, though it will usually be easier to source a turbocharged engine. Then do an engine transplant to this than add a turbo to a NA (naturally aspirated) engine.

Most manufacturers now have a turbo charged engine in their line up which would make a suitable donor for your project.

Turbo Terminology

Wastegates

A wastegate prevents excessive exhaust flow and will allow control over the boost produced. The wastegate diverts exhaust gases away from the turbo's propeller, reducing turbo lag.

Bov's diverter valves

A blow off or diverter valve controls the intake pressure. see our BOV article

Variable geometry turbos

Some modern engines have variable geometry turbos. These will allow the speed of the turbo to be altered by variations to the propeller angles.

Twin scroll

Twin scroll turbos take alternative inputs from the cylinders in two streams rather than one, and this benefits the cars power with a faster spool up time and less lag.

Turbo Lag

This is the delay before the turbo spins fast enough to provide boost, larger turbos tend to require more effort to spin them up but they can provide higher power levels at the top end.

ECU

This is the cars computer which controls ignition, fuel, spark and in many cases the turbos wastegate and boost control.

History of Turbocharger development

Let's finish with a look at the history of the turbocharger

The turbocharger design comes from Swiss engineer Alfred Buchi, and he previously worked on steam-powered turbines. He patented internal combustion turbo applications as far back as 1905.

Most aircraft-oriented applications enhance operational altitude by increasing air pressure and therefore compensating for low atmospheric pressure at high altitudes.

Fred Agabashian qualified for pole position at the Indianapolis 500 and led for 98 kilometers in a turbocharged vehicle in 1952!

The first turbocharged car was the 1962 Oldsmobile F-85 Turbo Jetfire, followed by the 1978 Mercedes-Benz 300SD.

In the 1980s, Yamaha, Kawasaki, and Suzuki added turbochargers to inline 4 engines to increase power without adding weight.

Further reading - in depth articles about turbos.

- Intro to turbos

- Turbos vs superchargers

- Fitting Turbo to a NA (naturally aspirated) engine

- Turbo upgrades

- Hybrid Turbos

- Twin Scroll Turbos

- Boost Controllers

- Screamer pipes

TorqueCars suggest that you join the friendly tuning forum and get some specific tips and advice for turbocharging your car model - we now have a dedicated turbo tuning forum.

Please Check out my YouTube channel, we're regularly adding new content...

PLEASE HELP: I NEED YOUR DONATIONS TO COVER THE COSTS OF RUNNING THIS SITE AND KEEP IT RUNNING. I do not charge you to access this website and it saves most TorqueCars readers $100's each year - but we are NON PROFIT and not even covering our costs. To keep us running PLEASE Donate here

If you liked this page please share it with your friends, drop a link to it in your favourite forum or use the bookmarking options to save it to your social media profile.

Feedback - What do You Think?

Please use our forums if you wish to ask a tuning question, and please note we do not sell parts or services, we are just an online magazine.

Help us improve, leave a suggestion or tip

Please watch this video and subscribe to my YouTube channel.

9 Responses to “How to add a turbo to a non turbo car.”

Click to accept YouTube Cookies & Play.

Click to accept YouTube Cookies & Play.

Very notifying i also am looking to put a turbo into my 1998 ford mustang v6 3.8 liter were do i even start to build up to it

i build a gt35 watercooled turbo on a toyota mr2 spider (1zzfe).

i am running with all stock,beside the maf converter (apex)..as long i dont go over the 7 psi it is all ok.

last dyno i had 239 hp (stock 138)so..100 ps more with 7 psi..not bad for this light car.the result is i need a extra gear (6 speed..??)

Don’t agree with lowering the CR to 7-1.

I have a 4G63 stroker with 8.7-1 ratio with 18 psi boost780cc injectors and a Haltec computer with a forged bottom end and touch wood zero problems to date 4 years and 15000klm (track and occasional weekend drive)

I have nasp engine with a 10:1 ratio. How much psi would i be able to run? And what injectors should i use?

Can i run turbo with same compression? Thanks julio

low comp turbos are more laggy off boost but can run more boost.

My car has 8.7-1 CR and 17psi

I’ve got an engine with a 9:1 cr what’s a safe boost pressure can i run on 94 octane fuel

The best article for a good experience with tubo world. In general it is a challenge to fit a turbo on simple [etrol engines. Need a lot of work and much money to be safe and smooth as required.

Thanks very Much for this Article I`ve learned to Much, there is no many info about Mod a N46 I have been searching for long time and nothing, this info was very helpful and I see that I can make my 118i BMW runs better without Swap the engine.

My Question is? I want to Turbo my N46 engine, I already have a M52 Garrett turbo small one,( low boost) I wanted to fix it without changing anything in the engine but exhaust and airflow. will it create me problems.

Great article,

It’s hard to out do oem now days , but people just want to be a little faster than the stock vehicle….for bragging rights. I chose a ecu “fooler” that tricks the stock ecu into raising boost but doesn’t over ride programming…It has built in safety’s for folks like me that olny know enough to be dangerous…It’s noticeably faster than stock,,but hasn’t blown anything in over 60k miles