Tips & Tricks for Building Stronger Engine

Pistons/Crankshafts

"We look at the pistons and crankshafts and explain them"

Another important aspect of building stronger internals for a performance engine is the pistons and crankshafts.

It is sometimes forgotten that a piston has an important role in upgrading the horsepower and torque figures for your engine.

It may be partly down to the tight margins and tolerances that are needed to work in your application, which ultimately means they are hard to replace, very expensive, and can cause a catastrophe if not calculated correctly.

Everything that moves within the engine has to be balanced and carefully matched too. Otherwise, you may get a host of nasty failures down the line.

When an engine is nicely balanced you can raise the redline, and this is where the peak power lies. If you are planning forced induction upgrades then making sure the bottom end of the engine is as strong as possible is a major consideration.

How a Piston Works

Using four-stroke setup as our basis, a camshaft rotates four times for every two rotations of the piston. The intake and exhaust valves open at specific points during this cycle.

The cycle can be summed up as Suck Squeeze Bang Blow (or Intake, Compression, Combustion and Exhaust).

All have different piston positions within the cylinder block/head of an engine as they move up and down.

Components of a Piston

A piston is comprised of the crown, or top surface.

The skirt, which are the sides supporting the crown, and the pin where it connects to the conrod.

The tops of each piston each have two to four grooves that are indented around the edge, close to the crown.

Named “ring lands”, these allow tightly fitting alloy rings to be placed on the piston to form a seal and avoid oil entering the combustion chamber by withstanding the pressure.

Different types of pistons

There are plenty of options for pistons, depending on your final purpose for the engine.

For stock, you need to replace with the same factory features for it to work, a supercharged or turbo charged engine needs low compression pistons, and performance naturally aspirated race engines need high compression pistons for greater peak power.

Flat Top Pistons

The top part of the piston has three main designs in today’s engines. Flat top pistons are most popular in terms of design.

They are a best all-rounder for compression ratios and valve clearances to provide the best power figures, which can be found in high performance engines as well as street cars.

Dished Pistons

Dished pistons however are shaped concavely, like a dish. Used in turbo or supercharged engines and help shrink compression.

The higher the compression ratio on these engines, the more risk of tearing the engine apart.

Domed Pistons

Domed pistons are for smaller combustion chambers and high compression rates.

This is the aim; however, they do create other issues such as incomplete combustion, slow burning, valve interaction and a less fuel-efficient setup. Being only suitable for specific applications.

They also require valve reliefs, which are small indents cut into the crown to stop valves hitting the piston.

Piston Materials and Processes

With the piston design, comes its manufacturing process. With three main processes, it is important to highlight the appropriateness of each.

Cast Pistons

With aluminum as the material choice, a mold is produced where molten liquid metal is poured, and after hardening and cooling, the piston is finished on a machining tool.

Advantages in this method include its repeatability at lower costs and casting is great for low to medium powered engines. However, casted pistons cannot endure higher engine compressions for racing applications.

Hypereutectic Pistons

Similar to casted aluminum pistons, Hypereutectic pistons add silicon to the composition.

This results in better tolerances for piston clearances, and an increase in strength over normal cast pistons, which is ideal for high-compression engines.

Known as the most popular method for upgraded street engines.

Forged Pistons

Machined from a solid billet of material. Creating a much stronger and tougher piston design, and ideal for extremely high compression figures.

These are much more expensive than casting and Hypereutectic methods, however. This is what we recommend at TorqueCars for turbo or supercharged engines.

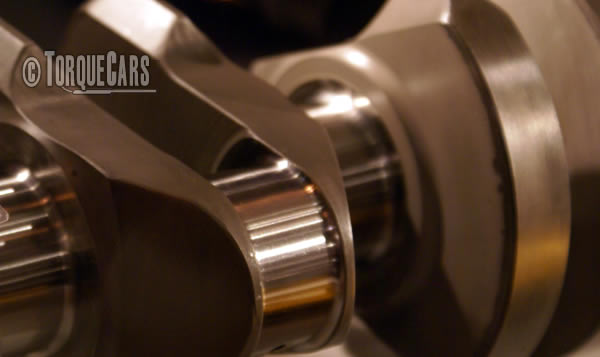

Upgrading a Crank to Improve Performance

The Crankshaft has a vital role and requirement to ensure the engine is using its pushing and pulling force from the pistons and conrods effectively.

Taking a constant battering from all the forces exerted on them, it is important to balance the optimum performance and tweaks needed to give you that cutting edge in racing.

Crank Manufacturing – Pros and Cons

Stock and road engines have either a cast iron or forged steel crankshaft.

With a greater need for fuel efficiency nowadays, forged is slowly becoming more popular in everyday applications because of its ability to withstand more power whilst staying small and lightweight.

Performance Cranks

There is a limit on how much a crank can withstand before it needs upgrading or adjusted.

This is where performance cranks come in, not only do they improve durability, but they also offer greater strength for higher rpm applications with less risk of splitting or winding.

With greater tolerances and precision manufacturing methods resulting in the following to be better setup for racing:

Journals

Journals are the round surfaces on the crank that allows a pivot point for conrods. They are polished smoothly on a performance engine for less friction and better movement.

Counterweights

Are used to offset the inertia of the rotating crank and for balancing the rotation.

They are given knife-edges. Which narrow the counterweight outer edges, resulting in a tapered design and ending up to a thin point, like a knife edge.

Helping reduce winding and drag within the engine, as well as better oil control.

Oil Holes

Also with a performance engine, oil holes are cross drilled and have chamfered edges to improve lubrication. With possibility of additional slots machined within journals, allowing for extra flow.

Nitriding and Nitrocarburizing Processes

Both involve the treatment of a low heat and low deformation thermochemical process that crankshafts undergo.

Nitriding for instance is heating the crank in an oven filled with nitrogen to about 500°C. Where Nitrocarburizing is the soaking of the crank in a salt bath consisting of a hot “ferric nitrocarburizing” solution.

In both instances, the nitrogen reacts with the metal to harden the outer layer of the crank at a depth of 0.5-0.75mm.

Incredibly, this doubles the hardness of the surface and does not affect the base material. It will however add cost to your crankshaft for this additional process, but it is something we recommend.

Cryo Treatment

Some are even cryogenically treated, which freezes the crank to hundreds below zero, and slowly increases the temperature back.

This allows re-alignment of the structure of the metal and is ideal for reducing potential issues in high-stress areas. Read more about this in our article on Cryogenic treatments

Conclusion

Ultimately, the base material and process to make the crank is just one element.

The design of the fillets at each journal, their counterweight shape, location, and size, how many oil holes there are, including the location of them, and the drilling method will all have a factor to play in upgrading your crankshaft for a race application.

Not only this, the additional processes of Nitriding/Nitrocarburizing or Cryo treatments will also play a heavy part, as you can see there are many different options out there.

For pistons too, we recommend forged pistons for high compression applications – however, choose the method that works best for your specific requirements.

Please join us in our forum to discuss your pistons and crank options in more detail with our members. It would also be worth reading our tuning articles to get a full grasp of the pros and cons of each type of modification.

Please Check out my YouTube channel, we're regularly adding new content...

PLEASE HELP: I NEED YOUR DONATIONS TO COVER THE COSTS OF RUNNING THIS SITE AND KEEP IT RUNNING. I do not charge you to access this website and it saves most TorqueCars readers $100's each year - but we are NON PROFIT and not even covering our costs. To keep us running PLEASE Donate here

If you liked this page please share it with your friends, drop a link to it in your favourite forum or use the bookmarking options to save it to your social media profile.

Feedback - What do You Think?

Please use our forums if you wish to ask a tuning question, and please note we do not sell parts or services, we are just an online magazine.

Help us improve, leave a suggestion or tip

Please watch this video and subscribe to my YouTube channel.

Click to accept YouTube Cookies & Play.

Click to accept YouTube Cookies & Play.