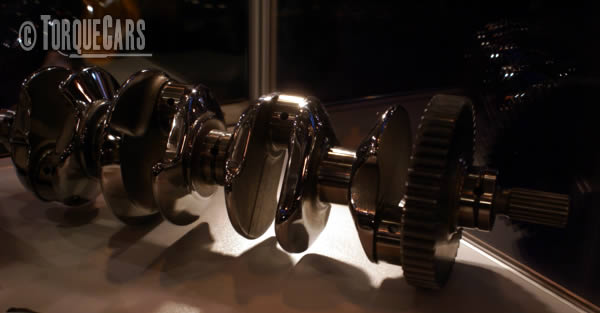

What is a crankshaft?

"Going all cranky!"

It connects the pistons to the driveshaft and converts the reciprocating motion of the pistons into rotational motion.

A flywheel is used to smooth out the motion. The more cylinders an engine has the more smooth the rotation will be.

A crankshaft will often have counterweights to help balance things out, without these weights or lobes there would be substantial vibration. This depends much on the design of the engine.

The design of the crankshaft has a large bearing on the performance and power output of the engine. The firing order of the pistons, the angle of the pistons and general configuration of the engine will be reflected in the design of the crankshaft.

By using a long or short throw crankshaft you alter the volume of the engine by amending the piston travel (stroke).

Increasing the stroke will boost your low RPM torque significantly.

If you were adding a turbo or supercharging you would want to reduce the engine compression and a crankshaft upgrade can be an easy route to do this when paired with short throw pistons.

Cranks can be forged or cast. Forged engines usually tolerate higher stresses and would be the choice of an engine tuner. Most manufacturers use cast crankshafts which is cheaper to produce and contains less manufacturing waste.

The heat used in casting and pounding used in forging can add stresses to the metal. A final heat and cool treatment under controlled conditions will help strengthen the metal.

You could also machine a crank using a billet of steel. They require heat treatment for strengthening but can be a cheap way to create a high performance crank. They do not suffer from the heat cycles of casting or pounding of forging so are stronger.

Remanufactured crankshafts can provide a good upgrade option if machined to a high tolerance.

Grinding away a layer gives a smooth uniform finish but this needs to be matched with undersized engine bearings.

Counterweights need to be carefully checked if remachining a crankshaft and you'd be a fool not to check the bearings and that the crank is straight. At each step of the remanufacturing process it is good to check for cracks and metal imperfections which could prove fatal if left unchecked.

Flat plane vs Cross plane crankshafts

A cross plane crank gives a 90 degree angle between crank throws, this smooths out the engine vibrations. If you look from one end down the shaft you'll note it looks much like an X or + in appearance. In a V8 engine you'll need to fire each side in pairs, right/right then left/left, and this is what gives a V8 that lovely off beat rumble sound.

A cross plane engine is easier to balance and gives a smoother power output. They also sound superb and is what most people think of when you talk about muscle car engines.

The flat plane crank is quite literally flat, when viewed from the side you'll see an l shape. In a V8 engine you'll be firing each side in sequence, left right left right. This flat plane setup allows very high rpm speeds and most race bred engines have a flat plane crank. The flat plane crank is much lighter than a cross plane crank.

You can't swap from a flat plane to a cross plane crank, your engine design, cylinder angle and firing order is key.

Lightened crankshaft benefits

Whenever you reduce the weight of rotational engine parts you get a performance boost. Less weight means it spins up and down faster, responding more quickly to engine power changes.

This gives faster acceleration but can bog down more easily as you lift off the power.

It also means the engine is more efficient using less power to alter the speed of the rotational mass that is the engine.

Lighter pistons, lighter rods and lighter counterweights all need to be fitted to maintain the engine balance.

Flying arm

Instead of all the crank pins having an intermediate main bearing the crank pins are connected directly via "flying arms". You'll usually find this setup in a V8 or v6 engine where the pistons are at alternative angles to the crank.

This ensures a even firing interval and as less bearings are required you have a lower weight which is good for performance. A flying arm crank is less rigid than a standard crank so will not tolerate high rpm speeds or very high power outputs.

Please Check out my YouTube channel, we're regularly adding new content...

PLEASE HELP: I NEED YOUR DONATIONS TO COVER THE COSTS OF RUNNING THIS SITE AND KEEP IT RUNNING. I do not charge you to access this website and it saves most TorqueCars readers $100's each year - but we are NON PROFIT and not even covering our costs. To keep us running PLEASE Donate here

If you liked this page please share it with your friends, drop a link to it in your favourite forum or use the bookmarking options to save it to your social media profile.

Feedback - What do You Think?

Please use our forums if you wish to ask a tuning question, and please note we do not sell parts or services, we are just an online magazine.

Help us improve, leave a suggestion or tip

Please watch this video and subscribe to my YouTube channel.

One Response to “Crankshafts – a complete performance guide”

Click to accept YouTube Cookies & Play.

Click to accept YouTube Cookies & Play.

Re lowering compression and short throw pistons IMO the best or correct way of lowering is by installing forged pistons that have a depression in the crown/top called a bowl that increases the volume of the combustion chamber which in turn lowers the static compression ratio