Best Modifications And Upgrades On The VW Group V5 (VR5)

"A look at the best upgrade options & Mods on this popular V5 engine."

The VW V5 engine is a five-cylinder gasoline engine developed by Volkswagen Group. It was primarily used in Volkswagen passenger cars during the late 1990s and early 2000s.

The V5 engine is part of the VR series of engines, which includes the VR6 engine as well. The name V-Reihenmotor," which translates to "V-inline engine" in English. It is a hybrid of a V and Inline engine.

VW dropped the R and referred to this as the V5, but many purists still refer to it as a VR5.

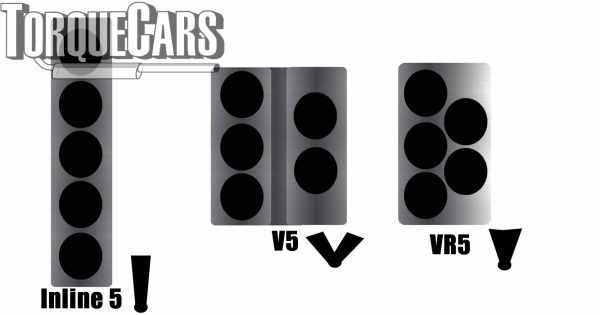

So R4 is an inline 4 cylinder, a V6 is a V layout engine with 3 banks to each V. VW merged the two, changing the V angle to just 15° enabling them to use just one head for each bank of cylinders.

I can't say it was the only V5 car engine, because Honda had created one but I don't think this ever made it to production. It is certainly the only VR5 engine in production.

Illustrated above is a top down view of various 5 cylinder configurations, and a front view of the engine below each one, to demonstrate the angle of the cylinders.

The VW group V5 is technically a VR5 as illustrated on the right, not a true V5 as per the middle image.

Power and Torque: The V5 engine offers immense low-end torque and high power output in the upper RPM range. It delivers a maximum torque of 220 Nm at 3600 RPM and a maximum power output of 110 kW at 6000 RPM.

Engine Specifications: The V5 engine has a V-angle of 15°, a displacement of 2324 cm³, a bore of 81.0 mm, and a stroke of 90.2 mm.

It operates with a compression ratio of 10.0:1 and follows a firing order of 1-2-4-5-3. The engine is equipped with Bosch Motronic M3.8.3 for mixture preparation and ignition.

Offset Design: Due to the 15° V-angle, the V5 engine is narrower than engines with larger V-angles. The cylinders are slightly offset to avoid overlaps, and each bank of cylinders is shifted outward by 12.5 mm.

This offsetting allows the engine to be mounted both longitudinally and transversely depending on the chosen application. Each layout requires different mounts and engine hardware so swaps between them can be a challenge.

For example the auxiliary drives differ: These longitudinally and transversely mounted V5 engines have very different drives for auxiliaries such as the alternator, coolant pump, auxiliary steering pump, and air-conditioning compressor.

The belt routing varies depending on the engine's mounting position so swaps between engines ideally require the same layout and mounting point.

Please see my video on Tuning Vw group VR5 and be sure to subscribe and support my new channel.

The VR5 engine was available in various Volkswagen models, including the Golf, Bora (Jetta), Beetle, Passat, and Sharan. It was also used in the SEAT Toledo and Alhambra models.

In terms of power levels, the VR5 engine offered a range of outputs depending on the specific variant and model.

The power output typically varied between 150 to 170 horsepower, although there were some high-performance versions that produced around 200 horsepower.

The torque output varied accordingly, providing good low-end torque for a smooth driving experience.

The key difference between the VR5 and V6 engines lies in the cylinder arrangement.

The VR5 engine features five cylinders arranged in a staggered "V" pattern, with one cylinder offset from the central line of the engine block.

Because an odd number of 5 cylinders are used and it has unequal intake and exhaust lengths it generates a truly unique engine sound, one of the most distinctive VW group engines from it's generation.

Benefits of a VR5 over V6 Design

This design allows for a more compact engine compared to a conventional straight-five configuration. In contrast, the VR6 engine has six cylinders arranged in a narrow "V" pattern, with two rows of three cylinders sharing a common cylinder head.

Although not much smaller the VR5 was chosen over the VR6 and it has become a highly sought after engine.

The advantages of the VR5 engine include:

- Compact Size: The VR5 engine's staggered cylinder arrangement allows for a more compact design, making it easier to fit into smaller engine bays. This can be particularly advantageous in compact or mid-sized vehicles.

- Smooth Operation: The five-cylinder configuration of the VR5 engine provides a unique sound and smooth operation compared to a conventional four-cylinder engine. The firing order of the five cylinders creates a distinctive exhaust note, offering a more refined driving experience.

- Torque Delivery: The VR5 engine's configuration allows for good low-end torque, providing ample power and responsiveness at lower RPMs. This can be beneficial for daily driving and city conditions, where low-end torque is often desirable.

- Balance and Vibration: The staggered arrangement of the cylinders helps to reduce vibration and improve engine balance compared to a four-cylinder engine. This contributes to smoother operation and a more refined driving experience.

Overall, the VR5 engine offers a unique combination of compact size, smooth operation, and good low-end torque delivery.

It provided a distinct alternative to the conventional four-cylinder and six-cylinder engines offered by Volkswagen, appealing to those seeking a balance between performance and fuel efficiency.

35mpg is at the upper end of what you can expect from a VR5 engine if you are reasonably careful.

That said the VR5 does not have a reputation as an economical engine, it was designed for power delivery in a time before legislators laid out stringent emissions regulations. It is unlikely we will ever see another VR5 engine today.

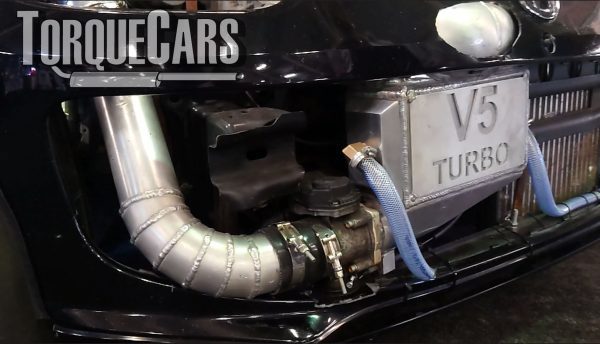

Turbo Upgrades on the V5

It is possible to add a turbocharger to the V5 engine. Turbocharging involves forcing additional compressed air into the engine's combustion chambers, resulting in increased power output.

By adding a turbocharger to the VR5 engine, you can significantly enhance its performance capabilities. The turbocharger utilizes the engine's exhaust gases to spin a turbine, which, in turn, compresses the incoming air before it enters the combustion chambers. This compressed air allows for a greater volume of fuel to be burned, resulting in increased power and torque.

The addition of a turbocharger to the V5 engine can deliver substantial power gains, typically resulting in a significant increase in horsepower and torque output.

The exact power levels achieved will depend on several factors, such as the size of the turbocharger, the boost pressure, and the supporting modifications made to the engine and fueling system.

It's worth noting that when adding a turbocharger to an engine, it's essential to consider other supporting modifications as well.

These may include upgrades to the fuel system, intercooler, exhaust system, and engine management system. These modifications ensure that the engine can handle the increased airflow and fueling demands associated with turbocharging.

Adding a turbocharger to the VR5 engine can transform it into a more potent and performance-oriented powerplant, enhancing acceleration and overall driving experience. However, it's important to approach such modifications with careful planning and ensure that the engine is properly tuned and supported to handle the increased stress and demands placed on it.

Tuning and Upgrading The V5.

For a stage 1 recommendation for the V5 engine, focusing on power upgrades while keeping the OEM pistons and rods, the following modifications are suggested:

- Software Tune: Invest in a software tune tailored to your desired power level. This will optimize the engine's performance and can accommodate a range of horsepower levels from 200 to 700 obviously depending on other mods. Aftermarket ECU options are a challenge on a 5 cylinder, we have traced one unit from Fueltech which is suitable, let us know if you are aware of any others out there.

- Exhaust Manifold: Upgrade the exhaust manifold to improve exhaust flow and enhance power delivery. A quality aftermarket exhaust manifold suitable for power levels between 200 to 700 horsepower is recommended especially when adding forced induction.

- Injectors: Depending on your target horsepower level, invest in suitable fuel injectors capable of supporting the desired power output.

- Camshaft Upgrades These alter the intake and exhaust valve timing durations allowing finer control over peak power and how the engine works.

- Head Spacer Plate: Install a head spacer to optimize the engine's airflow and potentially increase power and reliability. This will effectively be a compression lowering plate allowing you to run higher power figures especially with forced induction.

- Custom Timing Chain: Upgrade to a custom timing chain to ensure precise and reliable timing throughout the engine's RPM range.

- Custom Chain Tensioner: Install a custom chain tensioner to maintain proper tension on the timing chain, promoting smooth and reliable engine operation.

- Downpipe Flange: Purchase a downpipe flange for improved exhaust flow and compatibility with the upgraded exhaust manifold.

It's important to note that these modifications are considered primarily to be stage 1 (independent upgrades) and are aimed at optimizing power and performance while utilizing the OEM pistons and rods.

To ensure the best results, it is recommended to consult with a knowledgeable tuner or automotive professional who can customize the software tune and provide guidance on supporting modifications for the fuel system, clutch, and gearbox, which will depend on the specific power goals and usage requirements.

Here's a suggested build incorporating a V5 Turbo Kit with potential optional upgrades:

VR5 Turbo Kit - up to 550 HP:

- Short runner intake: A short runner intake is designed to optimize airflow and increase performance by reducing air turbulence within the intake manifold. It promotes better throttle response and power delivery.

- Fuel pump 270l/h: This high-flow fuel pump ensures an adequate supply of fuel to support the increased demands of a modified engine. It is capable of delivering a flow rate of 270 liters per hour.

- Boost controller (mechanical or digital): The boost controller allows for precise control and adjustment of the turbocharger's boost pressure. It can be either mechanical or digital, providing flexibility in managing and optimizing boost levels.

- 5x Fuel injector 470cc or 630cc: These upgraded fuel injectors have a higher flow rate compared to stock injectors. They deliver a greater volume of fuel to support increased horsepower and torque output.

- Pipework, intake and exhaust, fittings for proper oil and water cooling of the turbocharger (Silicone hoses and clamps quality is essential in a turbo project): Downpipe do-it-yourself set: The downpipe connects the exhaust manifold to the rest of the exhaust system. A do-it-yourself set typically includes the necessary components and fittings for the installation, allowing for customization and improved exhaust flow.

Alternative plug-n-play downpipe (+300 euros): This is an optional upgrade for the downpipe. It offers a plug-and-play solution, ensuring compatibility with the rest of the exhaust system and simplifying installation, albeit at an additional cost. - Boost gauge: Not essential but highly recommended. A boost gauge provides real-time monitoring of the turbocharger's boost pressure. It allows you to keep track of the boost levels and ensure they are within the desired range for optimal performance and engine safety.

- Intercooler: The intercooler is responsible for cooling the compressed air from the turbocharger before it enters the engine's combustion chambers. It increases the density of the air, resulting in improved performance and power output. The size options (e.g., 600x300x76mm or 550x230x65 or 550x180x65mm) refer to the dimensions of the intercooler, providing flexibility to choose the appropriate size for your specific application.

- Diverter or Blow-off valve: The diverter or blow-off valve is responsible for releasing excess boost pressure during deceleration or when the throttle is closed. It prevents compressor surge and protects the turbocharger.

- Turbo manifold V5 engines are not really suitable for a twin scroll design: The turbo manifold is responsible for collecting exhaust gases from the engine's cylinders and channelling them into the turbocharger.

- Turbo Garrett GTX3076R Garrett GTX2867R Garrett GTX3071R Garrett GT3582R GTX2871R

Choose a turbocharger based on your power goals and preferences some spool up more quickly whilst others provide much more top end power. - Compression lowering plate 2mm + spacer for belt tensioner: This component consists of a compression lowering plate and a spacer for the belt tensioner. The compression lowering plate reduces the engine's compression ratio, allowing for higher boost levels and increased power potential. The spacer for the belt tensioner ensures proper belt alignment and tension in the modified setup.

- t is necessary to have the ECU mapped to optimize the engine's performance and ensure safe operation with the modifications. It is recommended to consult with a professional tuner or engine management specialist to customize the ECU map according to your specific modifications and goals.

The compression lowering plate and spacer, along with the optional plug-n-play downpipe and turbo selection, offer further customization options and future proof your project.

Optional Upgrades:

- Reinforced clutch: Upgrading the clutch can ensure it can handle the increased power and torque of the turbocharged engine.

- 70mm catback exhaust: A larger diameter exhaust system can help improve exhaust flow and increase power gains.

- 100 or 200cpi cat: A higher-flow catalytic converter can further improve exhaust flow and performance gains.

- H-Beam rods: Upgrading to stronger H-Beam connecting rods can handle the increased stresses of higher power levels.

- Forged pistons: Forged pistons offer increased durability and strength compared to stock pistons, making them suitable for higher power applications.

- Reinforced bearings: Reinforced bearings can provide added strength and reliability under increased engine loads.

Please note that when modifying your vehicle with a turbocharger and aftermarket parts, it's essential to ensure proper tuning and engine management. Consult with an experienced tuner or automotive professional to ensure the engine is optimized for the increased power and modifications.

An alternative performance upgrade to consider is a supercharger. A supercharger can provide a significant boost in power while potentially offering better fuel economy compared to ITBs. However, it's important to note that once you delve into extensive tuning and modifications, focusing on fuel economy may become less of a priority.

Additionally, it's crucial to consider the overall reliability and durability of the engine and supporting components when targeting higher power gains. Upgrading the necessary supporting systems such as cooling, fuel delivery, and engine internals will contribute to a more reliable and robust build.

Fast Road Camshafts

In addition to the VR5 Turbo Kit and optional upgrades, another significant improvement to consider for the V5 engine is a fast road camshaft with a duration of around 260° to 270° (it seems a good compromise between power and drivability):

Piper offer a good cam upgrade for the VR5 engines, and KentCams and other camshaft specialists may offer a regrind on the stock cams.

NB: The VR5 ECU: The VR5 engine features an engine control unit that drives the intake camshaft through an intermediate shaft. It utilizes single chains for the camshaft drive and includes tensioners actuated by the oil circuit..

By upgrading to a fast road camshaft it will also complement a turbocharging setup, allowing for even greater performance gains and an exhilarating driving experience.

To fully exploit the potential of the modified camshaft, it is important to have the engine properly tuned and optimized for the new cam profile, ensuring optimal performance and reliability.

Consulting with a professional tuner or engine builder is advised to achieve the best results from the camshaft upgrade.

Individual Throttle Bodies

Intake throttle bodies (ITBs) can be a tempting upgrade for enthusiasts seeking to improve engine performance and achieve an enhanced sound.

However, there are several challenges to consider, particularly when it comes to implementing ITBs on a MKIV V5 engine.

One of the main obstacles is the requirement to remap the engine to run without the Mass Air Flow (MAF) sensor.

ITBs typically involve removing the MAF sensor, which necessitates recalibrating the engine control unit (ECU) to accurately measure and adjust fuel and air mixture.

This remapping process can be complex and may require the use of a standalone ECU, such as the MegaSquirt or Fueltech (finding ECU's that work on a 5 cylinder engine can be a challenge though), for more precise control and live mapping capabilities.

Furthermore, the VR5 engine is known for its relatively poor fuel economy. Adding ITBs to the engine can exacerbate this issue even further. While the sound generated by ITBs may be exhilarating, the practicality and fuel efficiency trade-offs may outweigh the benefits for many drivers.

Additionally, the VR5 engine has a unique cylinder arrangement, which can contribute to an unbalanced feel. The electronics and ECU of the engine play a crucial role in smoothing out its operation and making it tractable. Modifying the intake system with ITBs or carburetors would require careful consideration and a proper standalone ECU for precise tuning and optimization.

In conclusion, while ITBs can offer an enticing sound and potential performance gains, implementing them on a MKIV VR5 engine presents significant challenges. The need for remapping, potential fuel economy issues, and the requirement for a standalone ECU make it a less practical option for many enthusiasts. Considering alternative upgrades, such as a supercharger, may provide a more workable solution for achieving power gains while maintaining a balance between performance and fuel efficiency.

Oil Lubrication: The oil pump is driven by the intermediate shaft, and the oil cooler and oil filter are located in the engine console. Different oil filter types are used for longitudinally and transversely mounted engines.

Flywheel Upgrades

Dual-Mass Flywheel: The VR5 engine is equipped with a dual-mass flywheel, consisting of primary and secondary centrifugal masses interconnected by a spring/damping system.

The dual-mass flywheel reduces vibrations and noise transmitted to the gearbox, resulting in improved ride comfort, less wear, and higher fuel efficiency at low engine speeds.

Some of the problems with lighter or single mass flywheels include

Increased Vibration:

Dual mass flywheels are specifically designed to dampen engine vibrations and provide a smoother driving experience.

By replacing it with a single mass or lighter flywheel, the level of vibration transmitted to the engine and drivetrain can significantly increase. This can lead to a rougher and less comfortable driving experience, especially at lower engine speeds.

Increased Gearbox Stress:

Dual mass flywheels help absorb and dampen torque fluctuations from the engine, reducing stress on the gearbox and transmission components.

When switching to a single mass or lighter flywheel, these torque fluctuations are not adequately dampened, which can put additional strain on the gearbox.

This increased stress may lead to premature wear and potential damage to the transmission.

Difficulty with Smooth Engagement:

Dual mass flywheels contribute to smoother clutch engagement, allowing for more gradual and controlled shifts.

With a single mass or lighter flywheel, the clutch engagement can become more abrupt and challenging to modulate.

This can result in jerky shifts, stalling, or difficulty finding the engagement point, especially for drivers who are not accustomed to the different clutch behavior.

Increased Wear on Components:

The use of a single mass or lighter flywheel can potentially increase the wear on other drivetrain components, such as the clutch disc, pressure plate, release bearing, and even the engine's crankshaft thrust bearing.

The altered flywheel characteristics can affect the overall system dynamics, potentially leading to premature wear or failure of these components.

Loss of Low-End Torque:

Dual mass flywheels contribute to improved low-end torque and drivability, particularly in stop-and-go traffic or when starting from a standstill.

By switching to a single mass or lighter flywheel, the rotational inertia and moment of the flywheel are reduced, resulting in a loss of low-end torque and potentially affecting the engine's responsiveness at lower RPMs.

Please help us improve these tips by sending us your feedback in the comments box below.

We love hearing about our website visitors projects, especially the mods done and which work best for you on your car.

Which helps us keep our guides and tips up to date helping others with their modified car projects. Your feedback and comments are used to keep this page up to date and help improve the accuracy of these articles which are kept updated and constantly revised.

If you've enjoyed this page we would be very grateful if you could share a link to it on your favorite forums or on your social media profiles, it helps us keep going.

Please Check out my YouTube channel, we're regularly adding new content...

PLEASE HELP: I NEED YOUR DONATIONS TO COVER THE COSTS OF RUNNING THIS SITE AND KEEP IT RUNNING. I do not charge you to access this website and it saves most TorqueCars readers $100's each year - but we are NON PROFIT and not even covering our costs. To keep us running PLEASE Donate here

If you liked this page please share it with your friends, drop a link to it in your favourite forum or use the bookmarking options to save it to your social media profile.

Feedback - What do You Think?

Please use our forums if you wish to ask a tuning question, and please note we do not sell parts or services, we are just an online magazine.

Help us improve, leave a suggestion or tip

Please watch this video and subscribe to my YouTube channel.

Click to accept YouTube Cookies & Play.

Click to accept YouTube Cookies & Play.