Ive been asked to start a thread about my Cosworth engine. Im aware this is not a Ford site & that it may be a big turn off to many.

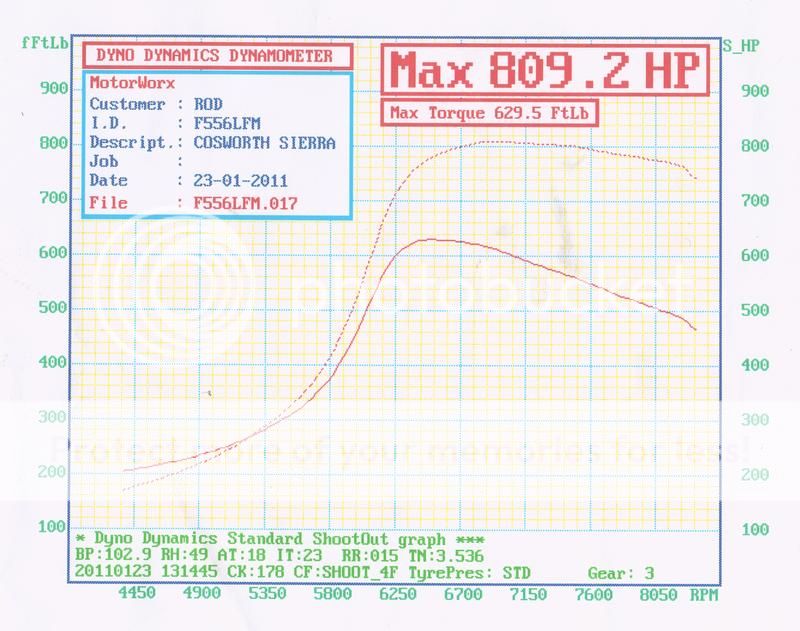

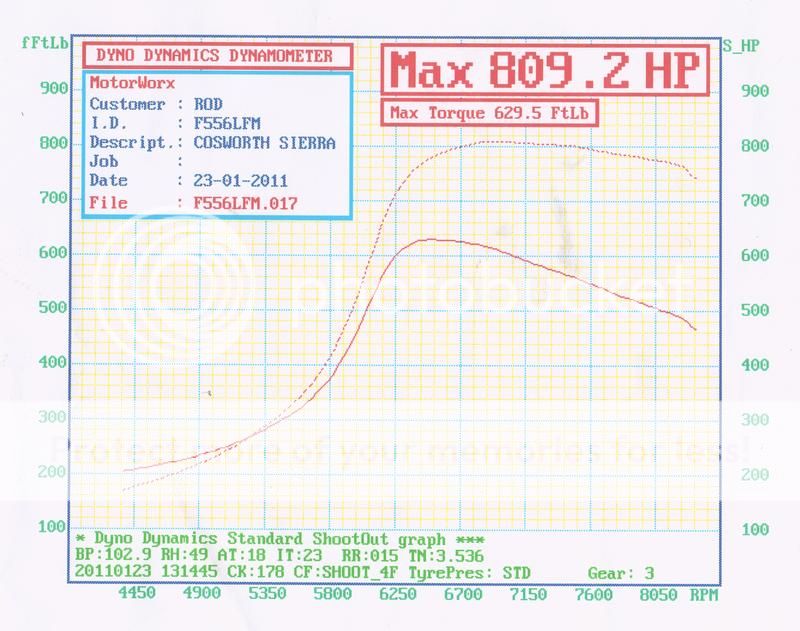

Best start with the engine that will be replaced. It was Dynoed on the Norris Designs Dyno in December 2008 the aim was to produce a genuine 800bhp road engine. Big Power is easy just Big everything & a 1000bhp is available but one look at the curve of such engines show no Power below 6k & completely un drivable on the road. Great drag engine though. To this aim ports were kept at 600bhp levels & the exhaust cam also kept mild. To get the geometry right for high revs the rods are 8mm longer & the pin moved in the new short skirt pistons. We upped CR from 7.2 : 1 to a completely un heard of 8.5:1 apparently that could not work according to rivals but they seem to have changed there opinions about that. The Turbo selected was a GT4202 which we knew would puff the boost. The aim was to overcome the limitations of the ports/cams with high boost. Well it worked result 838bhp/666ft-lb @ 2.9bar & a curve to die for with 2008 technology. Heres the graph its good for back then & completely useable on the road. We also moved to 16v not 12v thus running fuel pumps & CDI ignition at higher volts it meant no 'spark blowout' at high boost even with large plug gaps.

This engine soldiered on for 6k miles & then in July 2011 it started to knock. A check found Cylinder 3 & 4 big end shells worn although no drop in oil pressure was seen. We had know when we built it that reving beyond 9k was not good for a wet sump engine & this proved it. In 2010 we entered a RR shootout it was great fun trying to hold that Power on a RR its increase in Power not the actual peak Power that proved difficult. Tyres were let down, then strapped as hard as possible & then pumped up to 40 psi & to get grip 5 guys inside the car. Heaven knows how much Power this was losing but the old girl did good. Beating a 7 litre V8 .

Heres the old engine.

The new engine is start again. The Block has been further modified to supply oil to the rear of the block with a mod first used on WRC cars we should have done it on the last engine. Crank, Rods , pistons all new. The wet sump /breather system is replaced with a 4 stage dry sump sytem including a Turbo scavange. The head has .25mm bigger ports so still small & a 1 stage wilder exhaust cam is fitted. Valves remain standard. Its the battle to solve the YB vibration problems that have meant turning to aircraft tech. to try & solve. We have a front end rattle made for this engine & also real secret squirrel stuff with a ****** also used. Its a first time one off. To aid head gasket integrity I again turned to my pals in the Aircraft world knowing its light years ahead of your average Tuner. I sent a set of Mountune long studs to be analised. Mediocre at best built to a price. I asked what was possible a 100% increase in shear strength would cost £3500 for the stud set I didn't ask the price of the nuts. In the end I compromised at a 55% increase in shear strength for a mere £1000 with nuts at £23 each. Pushing boundaries is not a cheap game. Big progress has been made in ECU design so my old Autronics SM4 has been replaced by the latest Emtron KV8. The good old GT Turbo is now as dated as my taste in shirts & will be replaced by the mega quick spooling EFR 9180 my Tuner says the biggest advance in Turbo design ever. Its twin scrool so will sit on an Inconel manifold. The single RS500 Throttle body will be replaced by a set of Jenvey ITB'S.

Well that's the changes & should be ready by February 2016.

Fuel is also in a new era & we will use FTW Purple with the 9180 it will be out of puff circa 940bhp but spool about 800rpm sooner than the GT42.

I think that will be it but if the mood takes us we will take along the GT4202 & wind the Boost up. 1000bhp would require about 3.8 bar ish to reach but be risky & pointless.

Well that's it don't expect many to reach the bottom of that lot.

Best start with the engine that will be replaced. It was Dynoed on the Norris Designs Dyno in December 2008 the aim was to produce a genuine 800bhp road engine. Big Power is easy just Big everything & a 1000bhp is available but one look at the curve of such engines show no Power below 6k & completely un drivable on the road. Great drag engine though. To this aim ports were kept at 600bhp levels & the exhaust cam also kept mild. To get the geometry right for high revs the rods are 8mm longer & the pin moved in the new short skirt pistons. We upped CR from 7.2 : 1 to a completely un heard of 8.5:1 apparently that could not work according to rivals but they seem to have changed there opinions about that. The Turbo selected was a GT4202 which we knew would puff the boost. The aim was to overcome the limitations of the ports/cams with high boost. Well it worked result 838bhp/666ft-lb @ 2.9bar & a curve to die for with 2008 technology. Heres the graph its good for back then & completely useable on the road. We also moved to 16v not 12v thus running fuel pumps & CDI ignition at higher volts it meant no 'spark blowout' at high boost even with large plug gaps.

This engine soldiered on for 6k miles & then in July 2011 it started to knock. A check found Cylinder 3 & 4 big end shells worn although no drop in oil pressure was seen. We had know when we built it that reving beyond 9k was not good for a wet sump engine & this proved it. In 2010 we entered a RR shootout it was great fun trying to hold that Power on a RR its increase in Power not the actual peak Power that proved difficult. Tyres were let down, then strapped as hard as possible & then pumped up to 40 psi & to get grip 5 guys inside the car. Heaven knows how much Power this was losing but the old girl did good. Beating a 7 litre V8 .

Heres the old engine.

The new engine is start again. The Block has been further modified to supply oil to the rear of the block with a mod first used on WRC cars we should have done it on the last engine. Crank, Rods , pistons all new. The wet sump /breather system is replaced with a 4 stage dry sump sytem including a Turbo scavange. The head has .25mm bigger ports so still small & a 1 stage wilder exhaust cam is fitted. Valves remain standard. Its the battle to solve the YB vibration problems that have meant turning to aircraft tech. to try & solve. We have a front end rattle made for this engine & also real secret squirrel stuff with a ****** also used. Its a first time one off. To aid head gasket integrity I again turned to my pals in the Aircraft world knowing its light years ahead of your average Tuner. I sent a set of Mountune long studs to be analised. Mediocre at best built to a price. I asked what was possible a 100% increase in shear strength would cost £3500 for the stud set I didn't ask the price of the nuts. In the end I compromised at a 55% increase in shear strength for a mere £1000 with nuts at £23 each. Pushing boundaries is not a cheap game. Big progress has been made in ECU design so my old Autronics SM4 has been replaced by the latest Emtron KV8. The good old GT Turbo is now as dated as my taste in shirts & will be replaced by the mega quick spooling EFR 9180 my Tuner says the biggest advance in Turbo design ever. Its twin scrool so will sit on an Inconel manifold. The single RS500 Throttle body will be replaced by a set of Jenvey ITB'S.

Well that's the changes & should be ready by February 2016.

Fuel is also in a new era & we will use FTW Purple with the 9180 it will be out of puff circa 940bhp but spool about 800rpm sooner than the GT42.

I think that will be it but if the mood takes us we will take along the GT4202 & wind the Boost up. 1000bhp would require about 3.8 bar ish to reach but be risky & pointless.

Well that's it don't expect many to reach the bottom of that lot.