MasterAuron

Very Senior Member

I be giving my new front wishbones with Powerflex bushes an extra lick of paint today and something crossed my mind...Having a pair of tubular wishbones made.

This is a standard Mk1 Punto wishbone:

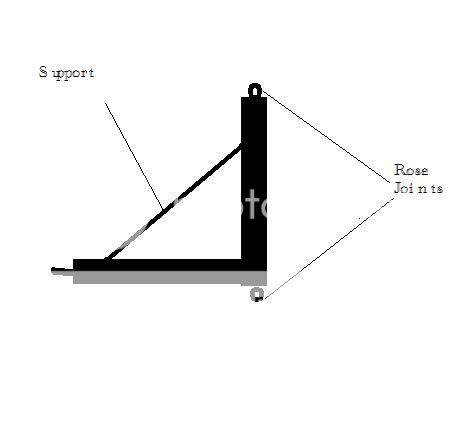

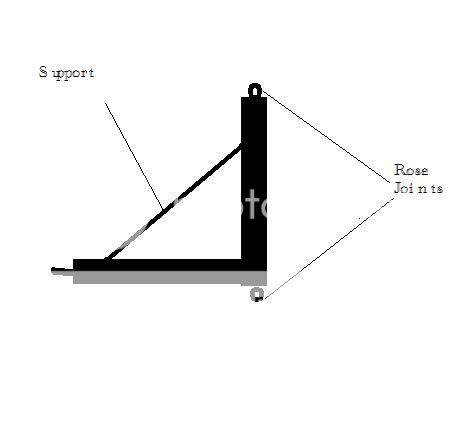

Now, I'm sure it wouldn't be a very hard job to fabricate a tubular wishbone to fit the car. Due to it's tubular nature and material I'm sure a wishbone of this fashion would not only be much lighter than the cast item, but stronger too. I was thinking something like this:

Due to the safety implications of such an item, I'm not prepared to have a go myself. Does anybody know what sort of company to approach regarding getting a pair designed and made? Rough cost? I'm hoping to keep costs as low as possible.

Also, with rose joints on the hub ends I can adjust camber without the camber adjustment bolts.

Opinions and advice much needed please?

This is a standard Mk1 Punto wishbone:

Now, I'm sure it wouldn't be a very hard job to fabricate a tubular wishbone to fit the car. Due to it's tubular nature and material I'm sure a wishbone of this fashion would not only be much lighter than the cast item, but stronger too. I was thinking something like this:

Due to the safety implications of such an item, I'm not prepared to have a go myself. Does anybody know what sort of company to approach regarding getting a pair designed and made? Rough cost? I'm hoping to keep costs as low as possible.

Also, with rose joints on the hub ends I can adjust camber without the camber adjustment bolts.

Opinions and advice much needed please?

I don't think it's beyond even your average engineer tbh.

I don't think it's beyond even your average engineer tbh.