jarrus

Pro Tuner

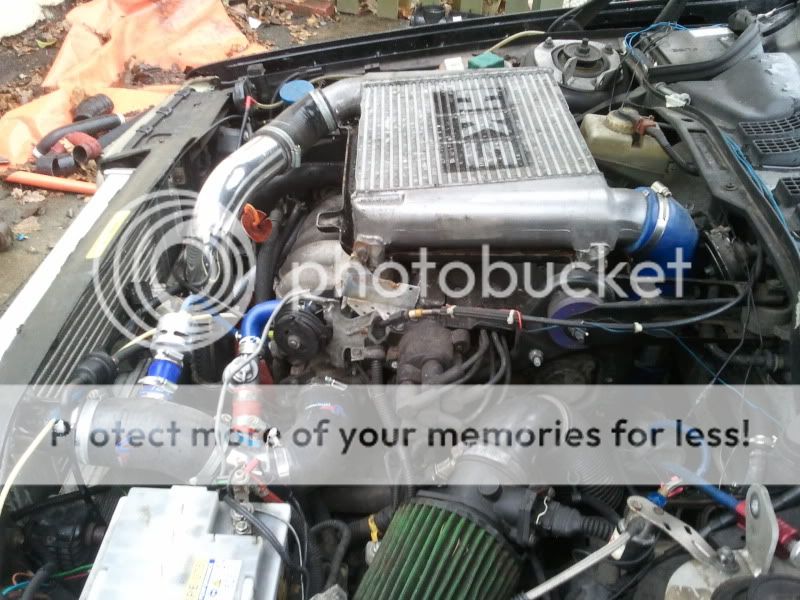

Yeah it is a bit "ghetto" as it were, the finished job should be good,

What's it drive like now?

What's it drive like now?

Last edited by a moderator:

Yeah it is a bit "ghetto" as it were, the finished job should be good,

What's it drive like now?

Is that a pop bottle?

The first run was with the maf disconnected, next stage is getting the unichip installed and mapped. I'll be handing that task over to my mate at Mike Evans Motorsport.Sounds ok there Claymore, were you happy with how the car performed on the run? so what's required to be done now before you turn the boost up?

I upped the boost today (bloodey hell it feels strong) and spent the day putting pipes back on...lol, I must have jacked the car up about 10 times today..lol

so I'v took off all my alloy joiners and will weld beads on them all tomorrow, I knew I'd have to do that anyway but I wanted to wait until I had all the pipe runs sorted.

Yep, that's all you need to do.Upped the boost on the turbo only I guess?

Does the beading just involve just welding a line of "crap" near the opening of each end of the pipe and then you clamp the silicon pipes the other side of that? I ask because I have access to stainless pipe but not the means to put the said beads on them, but if you can just put some weld on and that will do the same job then I can do that NP, I have a MIG and TIG welder (and the person to do it)

I'v taken the rubber seal off the back of the bonnet, so a lot of hot air will exit in front of the windscreen.That's really coming on now! I think you will need a bigger exit hole though.

lol. if you'v got fumes and hot oil spewing from your engine, you want it looked at.Is that wise? I thought that seal was there to protect the occupants from fumes/hot oil spewing from the engine.

Now with 12 months MOT

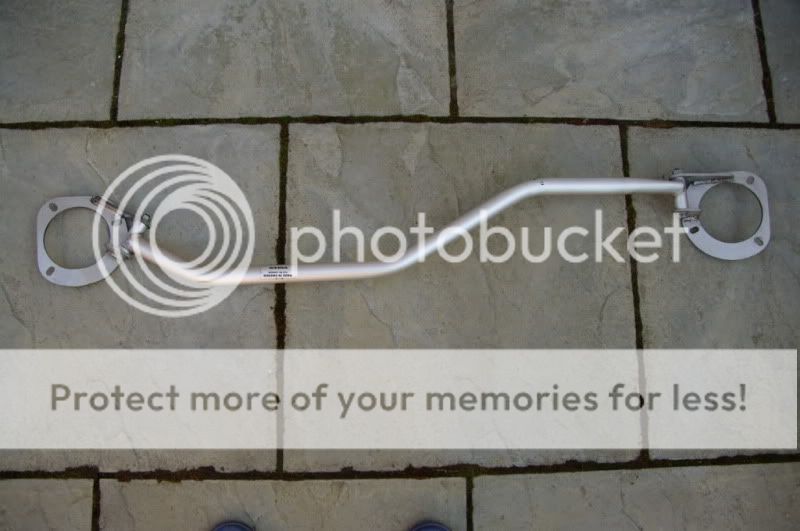

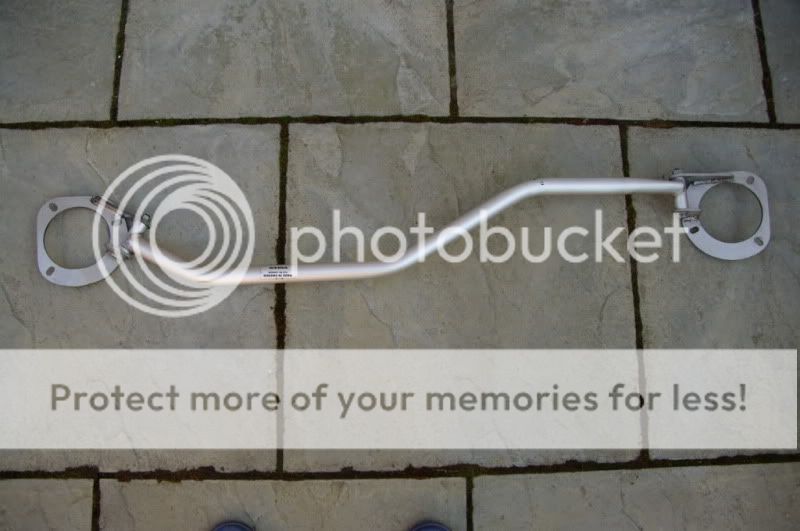

As you can see, its not far off the standard one, I just had to tweak it a bit, and yes she's nice and stiff again.Congrats on the MOT

Looking at your strut brace claymore, is this still ok taking into account all of the bends? does the car stiil feel stiffer and or display less torque steer?

I know you don't have too many options considering the size of the intercooler and its position. If the strut brace still does what it says on the tin, then this has given me a few ideas for the Beast!

As you can see, its not far off the standard one, I just had to tweak it a bit, and yes she's nice and stiff again.

Still waiting for a wiring diagramHad it mapped yet?

No more than before at the moment (about 280bhp) but with a bucket load more of torque.What are you realistically hoping for on the rollers?

| Thread starter | Title | Forum | Replies | Date |

|---|---|---|---|---|

| B | d24 engine | Volvo | 0 |