pgarner

TC ModFather

Ok my amp went bang a few weeks ago so had no bass since them. mate happen to say he was selling alot of stuff that he had as hes now going to be a dad. quick offer on his amp ad its mine.

plan is find another floor carpet and fill the spare wheel well with expanding foam.

cut out the shape for the amp in the foam and add channels for wires. and airflow, 2 8cm fans- one drawing and one pushing, should move enough. this will then be soaked in resin and if it works then i will have a solid enclosure housing the amp. cover with persex.

the floor carpet would then be cut to show the amp.

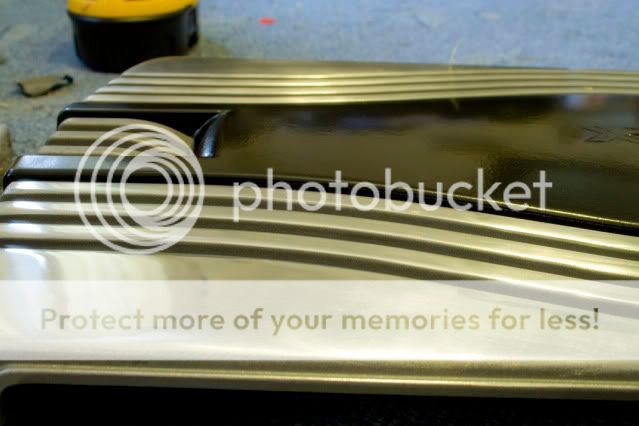

1st up im not a fan of the rough alloy look so this had to go

amp was stripped down and plastics removed - forgot to take proper start pics

start pic

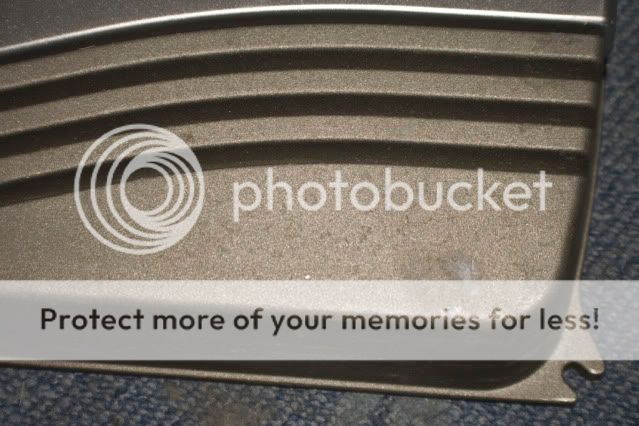

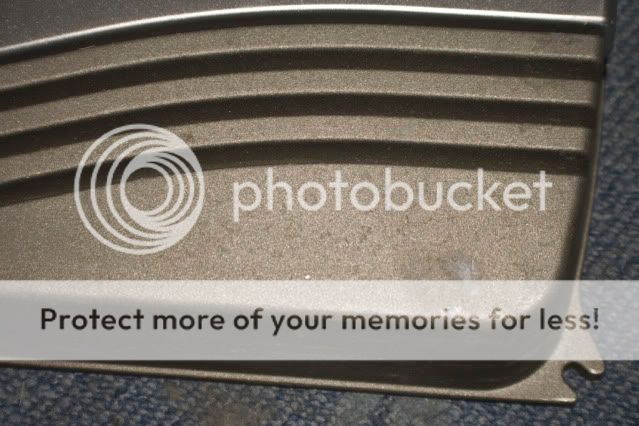

this was then treated to 80grit flap disc on the grinder.

then done by 120 grit by hand for around 30mins (didnt have a flap disc of this grit)

cover was washed then started with the 600grit and im up to here

fingers dont really feel like they belong to me now.

going to have a go with the 1500 later and hopefully ill get some polish to use a felt wheel on it tomorrow (didnt realise i had finished it)

the plastic cover was masked up along the xplode logo and cut out with a stanley.

scoured with a scotchbrite pad to key the surface.

couple of coats of primer

couple of coats of satin black and waiting to see what it looks like, thinking it might need a couple more before wet flatting it and polish

should look good the black against the mirror finish

plan is find another floor carpet and fill the spare wheel well with expanding foam.

cut out the shape for the amp in the foam and add channels for wires. and airflow, 2 8cm fans- one drawing and one pushing, should move enough. this will then be soaked in resin and if it works then i will have a solid enclosure housing the amp. cover with persex.

the floor carpet would then be cut to show the amp.

1st up im not a fan of the rough alloy look so this had to go

amp was stripped down and plastics removed - forgot to take proper start pics

start pic

this was then treated to 80grit flap disc on the grinder.

then done by 120 grit by hand for around 30mins (didnt have a flap disc of this grit)

cover was washed then started with the 600grit and im up to here

fingers dont really feel like they belong to me now.

going to have a go with the 1500 later and hopefully ill get some polish to use a felt wheel on it tomorrow (didnt realise i had finished it)

the plastic cover was masked up along the xplode logo and cut out with a stanley.

scoured with a scotchbrite pad to key the surface.

couple of coats of primer

couple of coats of satin black and waiting to see what it looks like, thinking it might need a couple more before wet flatting it and polish

should look good the black against the mirror finish