right everyone after the sale of the previous car fell through (less said the better) :wall:

i had a great bit of luck and dropped on this motor from a cracking guy from up cumbria :god:

its totally different spec wise to the white one i was going to get and i actually prefer that if im honest as its a lovely base to make a great car from and not ruin the oe looks/charm of it too much. :top:

its a 1990 car in red

totally standard engine wise apart from a receipt for some form of hybrid turbo

stainless system

lowered suspension

had a resto a few years ago and is in great shape nice and solid in all the usual areas.

also had an engine rebuild a few years ago

the car has not been on the road since 2014 but the current owner took the car for a pre mot on monday and it failed on the following

emissions too high

handbrake cable needs adjusting

spare wheel needs a tyre

one headlight not working

reverse light switch intermittent

and that was it so the plan is to give the car a real good full service including the following

oil and filter

ht leads and denso ik27 plugs

fuel filter

uprated frst fuel pump

coolant change

drive belt

cam belt and water pump kit

new set of wipers all round

new set of bulbs all round

the owner also informs me that the turbo will need a rebuild which is not a problem as it will go to my mate wilky for the said work and possibly a bit more of his magic work.

i also have my other mate who is a professional detailer booked in for the end of march to give the car a full paint correction detail and interior valet etc etc so the car will look spot on once done.

the plans are then to refit rebuilt turbo and then get the car an m.o.t. once this is done ill be calling msd for one of there set up sessions and if all well followed by there stage 3 conversion on the same day

looks wise with the car i dont really want to change anything apart from i think its crying out for the period 4" tailpipe on there D:

D:

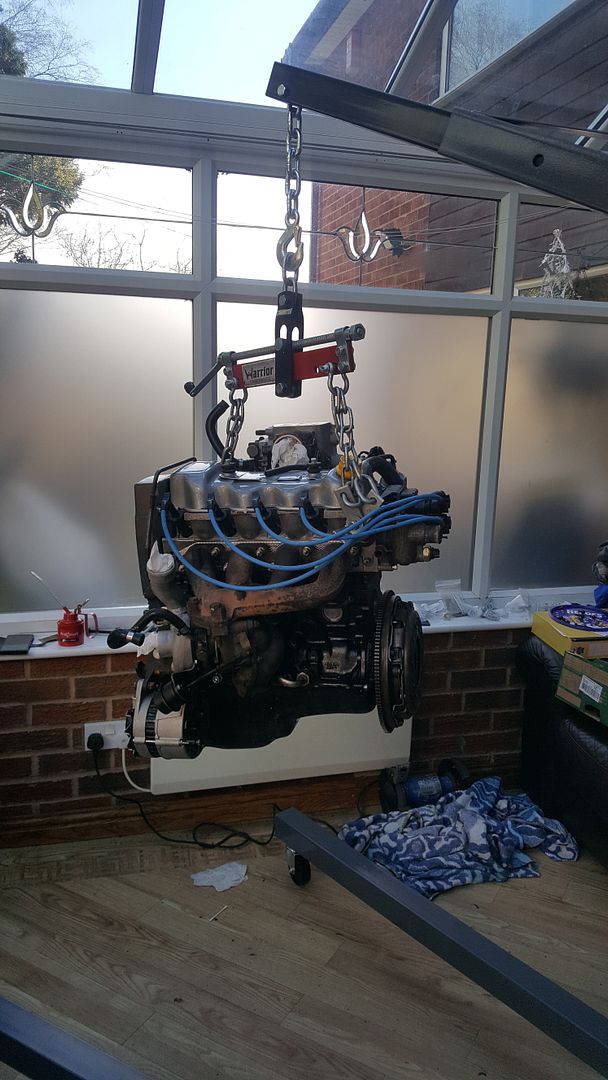

anyway enough babbling from me for now here are a few pics for you all

i had a great bit of luck and dropped on this motor from a cracking guy from up cumbria :god:

its totally different spec wise to the white one i was going to get and i actually prefer that if im honest as its a lovely base to make a great car from and not ruin the oe looks/charm of it too much. :top:

its a 1990 car in red

totally standard engine wise apart from a receipt for some form of hybrid turbo

stainless system

lowered suspension

had a resto a few years ago and is in great shape nice and solid in all the usual areas.

also had an engine rebuild a few years ago

the car has not been on the road since 2014 but the current owner took the car for a pre mot on monday and it failed on the following

emissions too high

handbrake cable needs adjusting

spare wheel needs a tyre

one headlight not working

reverse light switch intermittent

and that was it so the plan is to give the car a real good full service including the following

oil and filter

ht leads and denso ik27 plugs

fuel filter

uprated frst fuel pump

coolant change

drive belt

cam belt and water pump kit

new set of wipers all round

new set of bulbs all round

the owner also informs me that the turbo will need a rebuild which is not a problem as it will go to my mate wilky for the said work and possibly a bit more of his magic work.

i also have my other mate who is a professional detailer booked in for the end of march to give the car a full paint correction detail and interior valet etc etc so the car will look spot on once done.

the plans are then to refit rebuilt turbo and then get the car an m.o.t. once this is done ill be calling msd for one of there set up sessions and if all well followed by there stage 3 conversion on the same day

looks wise with the car i dont really want to change anything apart from i think its crying out for the period 4" tailpipe on there

anyway enough babbling from me for now here are a few pics for you all

your work and the "workshop" as well

your work and the "workshop" as well

.

.