HugoBoss

The Torque Meister

O wow that looks good, stunning work O.G

Day 29

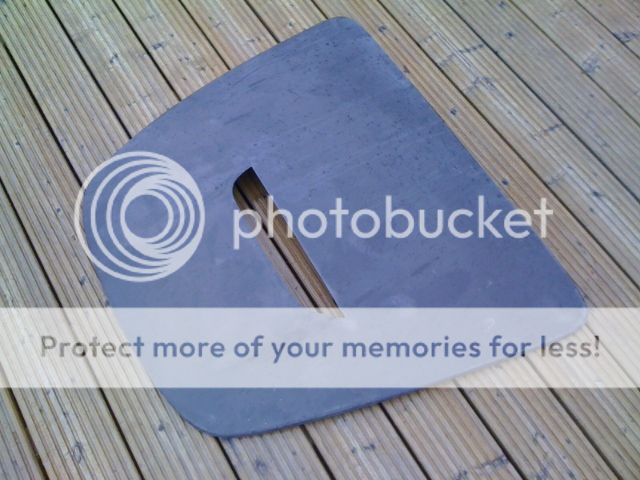

Trundled down to Southampton to pick up my original GF doors from Nick at Carbon Weezel. We discussed a few issues with the CF doors he is making which we resolved and we agreed that the doors woudl be ready fo rme to pick up at the end of February.

Whilst there a certain doctor rang up to give them more grief. One of the reasons my doors are taking so long is this bugger keeps giving them more work with short deadlines. If I ever find out who he is..............

Day 29

Trundled down to Southampton to pick up my original GF doors from Nick at Carbon Weezel. We discussed a few issues with the CF doors he is making which we resolved and we agreed that the doors woudl be ready fo rme to pick up at the end of February.

Whilst there a certain doctor rang up to give them more grief. One of the reasons my doors are taking so long is this bugger keeps giving them more work with short deadlines. If I ever find out who he is..............

How did I miss this post? :embarrest:

I don't know, but do you have any idea who he might be? Sounds like a right old PITA to me

The OG Mobile...