You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

At Last!. I have started on my car ;-) PART 2

- Thread starter pgarner

- Start date

Hi, anyone still on here?

Since mid 2020 I have done very little work on the car, a combination of going mad with it at the start of lockdown, then building an entertainment suite in the barn along with a putting course and a mini golf course, not forgetting the go kart track.

However, I have come to the conclusion that I will never finish the car without help. So, the car is going in to Geoff Page Racing to have the wiring commissioned and the engine fired up. My son, who works there, will be in charge of the work so no worries there.

Once it gets there (they are full at the moment) it should take less than 2 weeks before I have a car that starts. I can then get on with the rest of the stuff needed and will have a strong incentive Won't be cheap at around £70/hr but will be worth it.

Won't be cheap at around £70/hr but will be worth it.

I will keep you abreast of progress.

Since mid 2020 I have done very little work on the car, a combination of going mad with it at the start of lockdown, then building an entertainment suite in the barn along with a putting course and a mini golf course, not forgetting the go kart track.

However, I have come to the conclusion that I will never finish the car without help. So, the car is going in to Geoff Page Racing to have the wiring commissioned and the engine fired up. My son, who works there, will be in charge of the work so no worries there.

Once it gets there (they are full at the moment) it should take less than 2 weeks before I have a car that starts. I can then get on with the rest of the stuff needed and will have a strong incentive

I will keep you abreast of progress.

I was beginning to wonder if you had fallen off your perch and gone off to meet St Peter at the pearly gates.

Last edited:

Good to hear from you buddy, I'm still around. I'm always eager to see what you've been upto and how project quarter mile is going.

It sounds like you have a good plan, and I wish you all the best in your progress.

I'm sure our server will be glad when you finish this really long and extremely popular thread.

It sounds like you have a good plan, and I wish you all the best in your progress.

I'm sure our server will be glad when you finish this really long and extremely popular thread.

Hi Waynne, trust that you and your family are well..

Started to make a TODO list, always a scary thing to do as they are never ending.

In no particular order:

Fit handle to driver's door

Cut and fit door polycarbonate windows

Fit front and rear screens

Fit wiper assembly

Complete interior (all carbon)

Secure passenger seat. Weighs less than 1kg so will need some support

Add a couple of tubes to roll cage behind seats to make it FIA compliant

Decide on wheel sizes and tyres

Bleed brakes

Set up suspension and steering (caster, camber, toe etc)

Set ride height

Fit door net

Make and fit propshaft loop (shroud)

Finish body and spray (Colour and design a secret )

)

Fit lights

Finish underfloor panels

Secure pedal box (need to do this before car goes to GPR)

Check and tighten every nut and bolt (mark when done)

Secure Nitrous bottle in boot

Repack and fit parachute

Buy and fit race harnesses

Fit wheelie bar

Etc.....

Started to make a TODO list, always a scary thing to do as they are never ending.

In no particular order:

Fit handle to driver's door

Cut and fit door polycarbonate windows

Fit front and rear screens

Fit wiper assembly

Complete interior (all carbon)

Secure passenger seat. Weighs less than 1kg so will need some support

Add a couple of tubes to roll cage behind seats to make it FIA compliant

Decide on wheel sizes and tyres

Bleed brakes

Set up suspension and steering (caster, camber, toe etc)

Set ride height

Fit door net

Make and fit propshaft loop (shroud)

Finish body and spray (Colour and design a secret

Fit lights

Finish underfloor panels

Secure pedal box (need to do this before car goes to GPR)

Check and tighten every nut and bolt (mark when done)

Secure Nitrous bottle in boot

Repack and fit parachute

Buy and fit race harnesses

Fit wheelie bar

Etc.....

That is quite a list. My TODO list is..

1> Make a TODO list

That is as far as I get, so you are many steps ahead of me.

Family is not too bad, the mother in law needs daily care and support which as you can imagine takes up loads of our time, but we are coping ok.

1> Make a TODO list

That is as far as I get, so you are many steps ahead of me.

Family is not too bad, the mother in law needs daily care and support which as you can imagine takes up loads of our time, but we are coping ok.

Yes, been there. Mum died last January so Dad is on his own for the first time in over 70 years! He is doing OK and my Sister lives only 5 minutes away (I'm over 40 minutes away) and he wants to say in their house for as long as possible. The sad thing is that he is lonely as their brothers and sisters and the few friends they had are mostly dead now. We can only do what we can do and he could well end up living with us. We did that with Mother-in-law so not a problem. I guess that's what (good) families are for.

Sorry to hear that. Yes it's all about supporting them and keeping them as comfortable as possible. Putting ourselves in their shoes helps us understand what they are going through doesn't it.

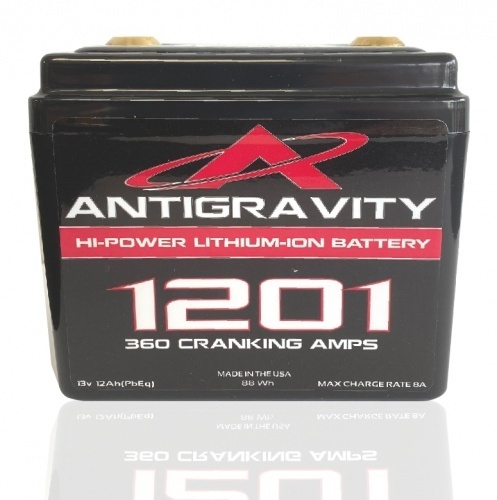

For anyone remotely interested in car batteries:

Approx 7 years ago I though that I was near to starting the car up so decided to get a battery. Being, as you are all no doubt aware, somewhat anal about the car's weight, I decided to grit my teeth and go for a lithium jobbie. After a fair amount of research I settled on Antigravity Batteries as they seemed to give the best value for money and the lightest units. After a long chat with Peter we agreed that their YTX12-12 battery would best suit my needs.

As they are situated in Southend-on-Sea, only 30 minutes away, I popped down to see them. Peter handed me the battery and I thought that he was playing a trick on me with an empty case! But, no, this was the actual battery! (I weighed it when I got home and it is 953gms!!!) At £200 it wasn't cheap but the weight saving over a traditional battery was amazing.

Over the years I have kept it topped up (they need very little maintenance as opposed to lead/acid ones) every 6 months or so. The topping up process it quite long winded as the charger (you need a Lithium battery charger) goes though quite a long checking and monitoring process which can take over a day.

However, last week was different. Even after 3 days it never got out of the testing phase so I thought that it had died. Rang Antigravity and spoke to Peter who suggested that, after 7 years of inactivity, it could be on its way out. They do a replacement that is 110gms heavier but ridiculously small (115mm x 80mm x 108mm). So off I go to Southend.

When I got there Peter took my battery to test it. The tests he could do without hooking it up for 24 hours seemed to indicate that it was OK. He suggested that I fit it to a car to see if it works before forking out £260 for a new one. Got home and put it on the Fox and it started! So the plan now is to fit it and see if it works once the car is ready.

I can't fault their service. I quite expected to walk out with a new battery as he could have quite easily convinced me that my battery was on its way out and sold me a new one.

Regarding their batteries. The manufacture works on the mantra of under promise and over deliver. Although the 1201 sates 360 cranking amps Peter has tested them at over 700! Enough cranking amps for a measly 2 litre methinks

#NotSponsored

Approx 7 years ago I though that I was near to starting the car up so decided to get a battery. Being, as you are all no doubt aware, somewhat anal about the car's weight, I decided to grit my teeth and go for a lithium jobbie. After a fair amount of research I settled on Antigravity Batteries as they seemed to give the best value for money and the lightest units. After a long chat with Peter we agreed that their YTX12-12 battery would best suit my needs.

As they are situated in Southend-on-Sea, only 30 minutes away, I popped down to see them. Peter handed me the battery and I thought that he was playing a trick on me with an empty case! But, no, this was the actual battery! (I weighed it when I got home and it is 953gms!!!) At £200 it wasn't cheap but the weight saving over a traditional battery was amazing.

Over the years I have kept it topped up (they need very little maintenance as opposed to lead/acid ones) every 6 months or so. The topping up process it quite long winded as the charger (you need a Lithium battery charger) goes though quite a long checking and monitoring process which can take over a day.

However, last week was different. Even after 3 days it never got out of the testing phase so I thought that it had died. Rang Antigravity and spoke to Peter who suggested that, after 7 years of inactivity, it could be on its way out. They do a replacement that is 110gms heavier but ridiculously small (115mm x 80mm x 108mm). So off I go to Southend.

When I got there Peter took my battery to test it. The tests he could do without hooking it up for 24 hours seemed to indicate that it was OK. He suggested that I fit it to a car to see if it works before forking out £260 for a new one. Got home and put it on the Fox and it started! So the plan now is to fit it and see if it works once the car is ready.

I can't fault their service. I quite expected to walk out with a new battery as he could have quite easily convinced me that my battery was on its way out and sold me a new one.

Regarding their batteries. The manufacture works on the mantra of under promise and over deliver. Although the 1201 sates 360 cranking amps Peter has tested them at over 700! Enough cranking amps for a measly 2 litre methinks

#NotSponsored

What a great company, totally deserving of the word of mouth promotion they are getting. Thanks for highlighting them to us.

Awesome, the beast is ALIVE!

We did discover a rather expensive problem. We have no throttle because this ECU has no drive by wire capability. When I bought it we were using cable as DBW was not reliable enough for our application. This was quite a few years ago and we have since upgraded to DBW, not realising the ECU issue. A new one has been ordered but I have not been told the cost! I will pay directly rather than have the workshop add their cut, but they also get a 25% discount which I can have so that eases the pain a tad. Hopefully I can sell my, basically, unused ECU to soften the blow.

Our other issue is the PDM. When trying to load the installation software we are getting a fail message. My son will talk to HP Electronik in Denmark via Teamviewer tomorrow to get them to install it remotely. Fingers and toes crossed.

Our other issue is the PDM. When trying to load the installation software we are getting a fail message. My son will talk to HP Electronik in Denmark via Teamviewer tomorrow to get them to install it remotely. Fingers and toes crossed.

Tell me about lithium batteries, can you use a conventional charger on them? Does the stock charge system in car work ok or does it need to be modified to make it work?

They are great, as long as you know what you are doing and don't buy cheap! They require a bespoke charger designed for lithium batteries (don't buy cheap copies). It goes through various health checks before charging. Best. You can use a standard charger if it doesn't have a de-sulphate mode, but you won't get a full charge (13.2 rather than 13.8v) or health checks. Original car charging system works fine.Tell me about lithium batteries, can you use a conventional charger on them? Does the stock charge system in car work ok or does it need to be modified to make it work?

Last edited:

Car is back !

First task is to sort out the isolator so we can start on the button.

Then fill with clutch and brake fluid and check for and fix leaks.

Finish Pneumatic lines to compressor and set up gear change system, fingers crossed that I fitted a big enough actuator.

Fill with coolant. I had planned to use Evans waterless coolant but decided against for a couple of reasons. Santa Pod hate the stuff so will ban you if they find out. But more importantly I have just discovered that, due to its viscosity, it robs engine power! So boring old water and antifreeze it is. Now I need to sell the stuff.

First task is to sort out the isolator so we can start on the button.

Then fill with clutch and brake fluid and check for and fix leaks.

Finish Pneumatic lines to compressor and set up gear change system, fingers crossed that I fitted a big enough actuator.

Fill with coolant. I had planned to use Evans waterless coolant but decided against for a couple of reasons. Santa Pod hate the stuff so will ban you if they find out. But more importantly I have just discovered that, due to its viscosity, it robs engine power! So boring old water and antifreeze it is. Now I need to sell the stuff.

I can't get a beep out of the battery isolator. Spoke to Cartek and I am sending it to them for testing tomorrow. This is going to be expensive, either a new isolator or a wiring fault finding exercise

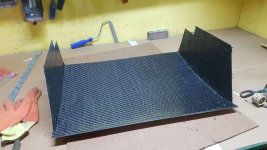

Anyway, on to more interesting stuff. Made the radiator/intercooler shroud pattern today. Next job is to cut it out of aluminum and make that into a mould. That will be Thursday's task as out tomorrow.

Anyway, on to more interesting stuff. Made the radiator/intercooler shroud pattern today. Next job is to cut it out of aluminum and make that into a mould. That will be Thursday's task as out tomorrow.

Good to see you back on the job tinkering away with your enviable skill set and your obsession with lightening everything. Hopefully I will live long enough to see the worlds fastest and lightest Lotus set new records.

Hang on until next springGood to see you back on the job tinkering away with your enviable skill set and your obsession with lightening everything. Hopefully I will live long enough to see the worlds fastest and lightest Lotus set new records.

Similar threads