You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

At Last!. I have started on my car ;-) PART 2

- Thread starter pgarner

- Start date

Visited friends in Sherman Oaks, north of Los Angeles today (Sunday) Whilst Julia chatted to Toni, Frank and I escaped to his garage to discuss Lotuses. I mentioned that I was impressed with the stiffness of the Reverie seats in his 211, how heavy are they?. He said he had a damaged one which he got out to show me. After a few minutes he showed me the damage. Then then dropped a bombshell. "Hey, why don't you take it home, you can easily repair the damage and it will save you having to make one" I asked, "How much do you want for it?" "Nothing" !!!!! We are flying back Business and have enough luggage allowance so just have to wrap it. As Kryten would say,"Engage smug mode"

It is double skinned and weighs 2.4kg. I can live with that

It is double skinned and weighs 2.4kg. I can live with that

What is it with America and the 110 volt mains and the light switches that go the opposite way? We had a washer dryer stacker that was 110v for the washer but 220v for the drier. The utilities were billed monthly instead of quarterly and were a whole lot more expensive than the UK.

Have you got a repair scheme drawn up for that seat? Is it Kevlar or graphite composite? I heard a story about the Lockheed Skunk works in Palmdale when they were building the Hopeless Diamond stealth fighter they had a lot of trouble with composite delaminations and they were using heated platens to repair wing skin panels only somebody left one switched on while they went for a coffee break and when they came back the platen was sagging through the lower skin. Not good.

Have you got a repair scheme drawn up for that seat? Is it Kevlar or graphite composite? I heard a story about the Lockheed Skunk works in Palmdale when they were building the Hopeless Diamond stealth fighter they had a lot of trouble with composite delaminations and they were using heated platens to repair wing skin panels only somebody left one switched on while they went for a coffee break and when they came back the platen was sagging through the lower skin. Not good.

Well, we are back home in one piece and no issues at Customs. We were going to go Red but a custom official stopped us before we entered to ask why we were going that way (I guess it was unusual). When we told him that we weren't sure whether we should declare an old car seat he said no. He then asked if we had anything worth over £400 and when we replied no he ushered us through Green.

Did a first dry fit of my 'new' driver's seat today. What does Prince Charming say when Cinderella puts on the glass slipper? Oh, yes......IT FITS!! My only concern is that the base of the seat is thicker than the one I made so I am not sure that my crash helmet will now clear the roof. I won't be able to check this until I have fitted the floor.

The seat I made (also in carbon), which is now relegated to the passenger side, doesn't look too out of place so I will use it.

Now I just need to make the seat brackets and decide whether to paint it black to match the passenger seat.

Did a first dry fit of my 'new' driver's seat today. What does Prince Charming say when Cinderella puts on the glass slipper? Oh, yes......IT FITS!! My only concern is that the base of the seat is thicker than the one I made so I am not sure that my crash helmet will now clear the roof. I won't be able to check this until I have fitted the floor.

The seat I made (also in carbon), which is now relegated to the passenger side, doesn't look too out of place so I will use it.

Now I just need to make the seat brackets and decide whether to paint it black to match the passenger seat.

T9 man

TC ModFather

Looking very nice Steve

The seat is carbon so repair is a piece of cake.

With all the practice you have had with CF you should be able to re-fettle that seat blindfolded

You can mod the roof line for helmet space like the Viper.

https://www.google.com.au/search?q=dodge+viper&biw=1680&bih=926&tbm=isch&imgil=4vAAjKoVhvfPnM%3A%3BGNcQixnRqMC4TM%3Bhttps%253A%252F%252Fw

.

Last edited:

T9 man

TC ModFather

I see what you are saying Steve, what's that bubble on the roof line on the drivers side all about?

I see what you are saying Steve, what's that bubble on the roof line on the drivers side all about?

Forgot that the driver had to wear a helmet at the track

At least the Viper had 2 raised sections for a more balanced look

T9 man

TC ModFather

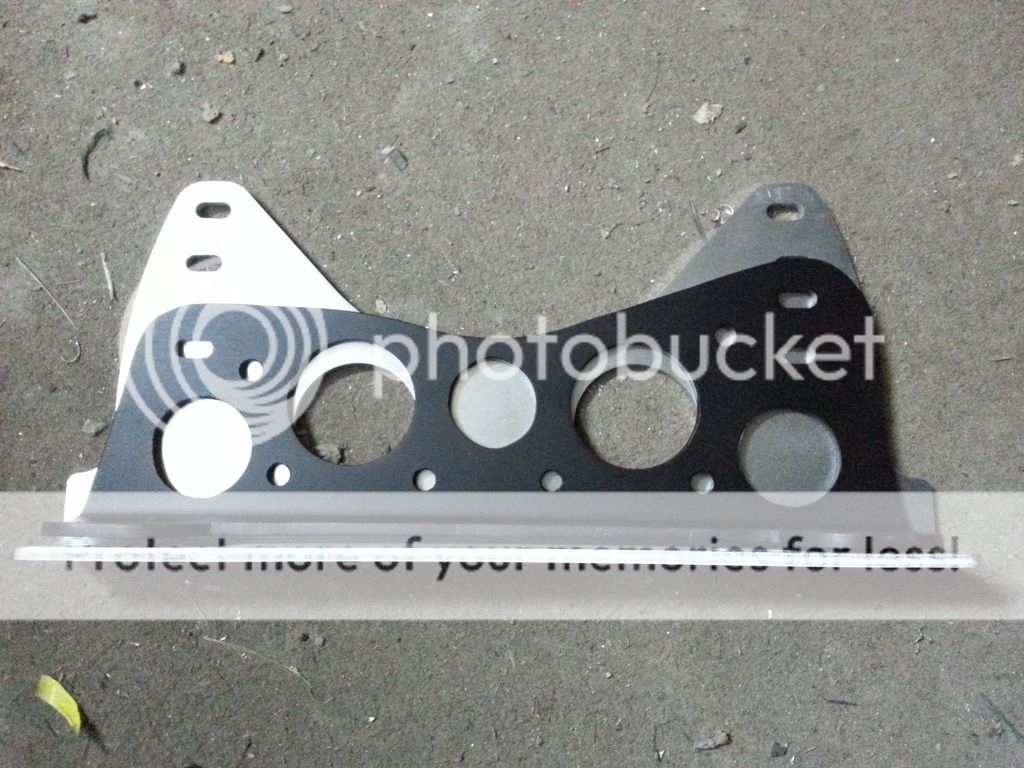

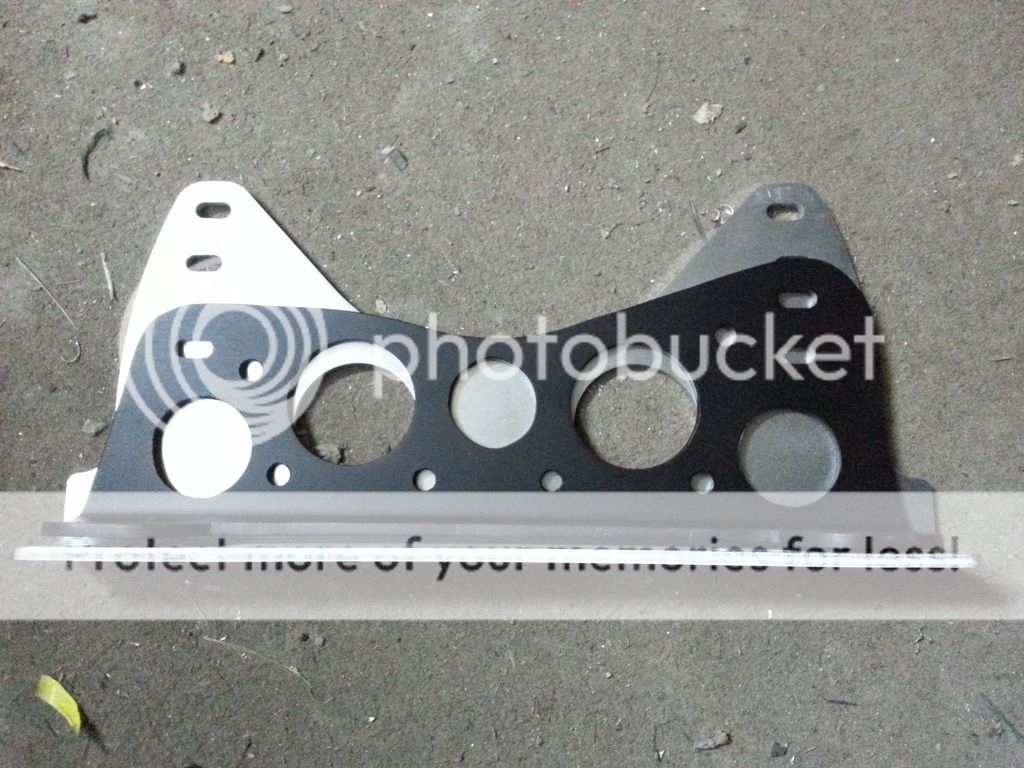

That's a very nice looking seat bracket as it is, weight reduction? You have no shame Steve

That's a very nice looking seat bracket as it is, weight reduction? You have no shame Steve

And your point is?

T9 man

TC ModFather

Ruining a lovely looking piece of engineering with more holes

Well as you say, it all adds up.

Well as you say, it all adds up.

Update. The £46 they were charging was only for the flat plates (dark bits) !!! £46 for two pieces of plate with a few holes drilled in them? I think not.

Instead I have ordered a pair of OMP brackets. Cost is £70, but to buy the aluminium would cost around £35 plus a few hours cutting and drilling. Sometimes time is more important than money.

Instead I have ordered a pair of OMP brackets. Cost is £70, but to buy the aluminium would cost around £35 plus a few hours cutting and drilling. Sometimes time is more important than money.

Very nice work OG! You'll be finished soon

A quick check using double sided tape confirmed that glove box lid fits OK.

I now have a box full of spare titanium bolts, not sure how this happened. I know that I bought the bolts to hold the body to the chassis (14) and am now using only 4 due to body mods, but that doesn't explain the others. Oh, well, I am sure I will find a use for them before the car is running

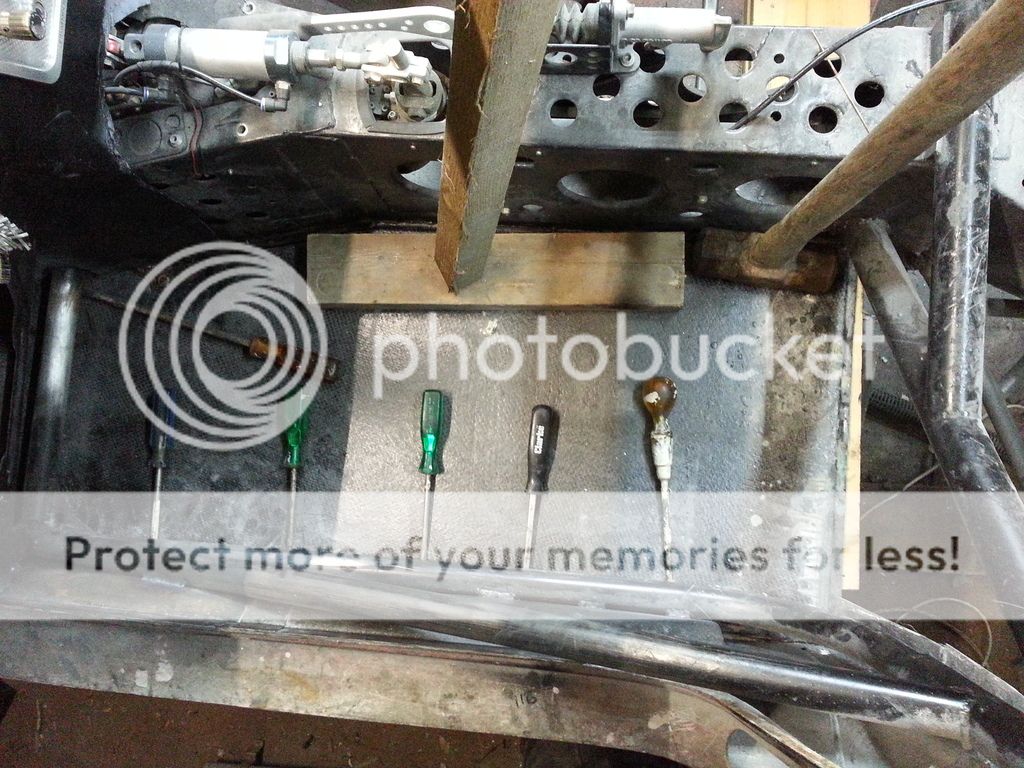

A rough idea of what I will be removing from the seat brackets.

I now have a box full of spare titanium bolts, not sure how this happened. I know that I bought the bolts to hold the body to the chassis (14) and am now using only 4 due to body mods, but that doesn't explain the others. Oh, well, I am sure I will find a use for them before the car is running

A rough idea of what I will be removing from the seat brackets.

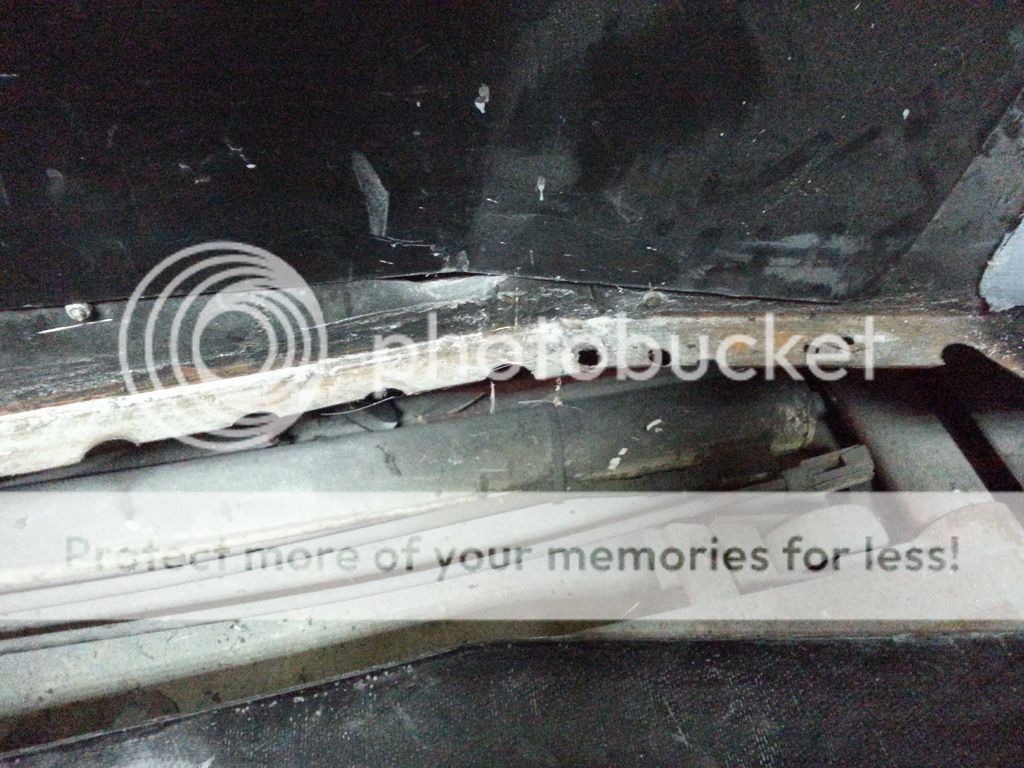

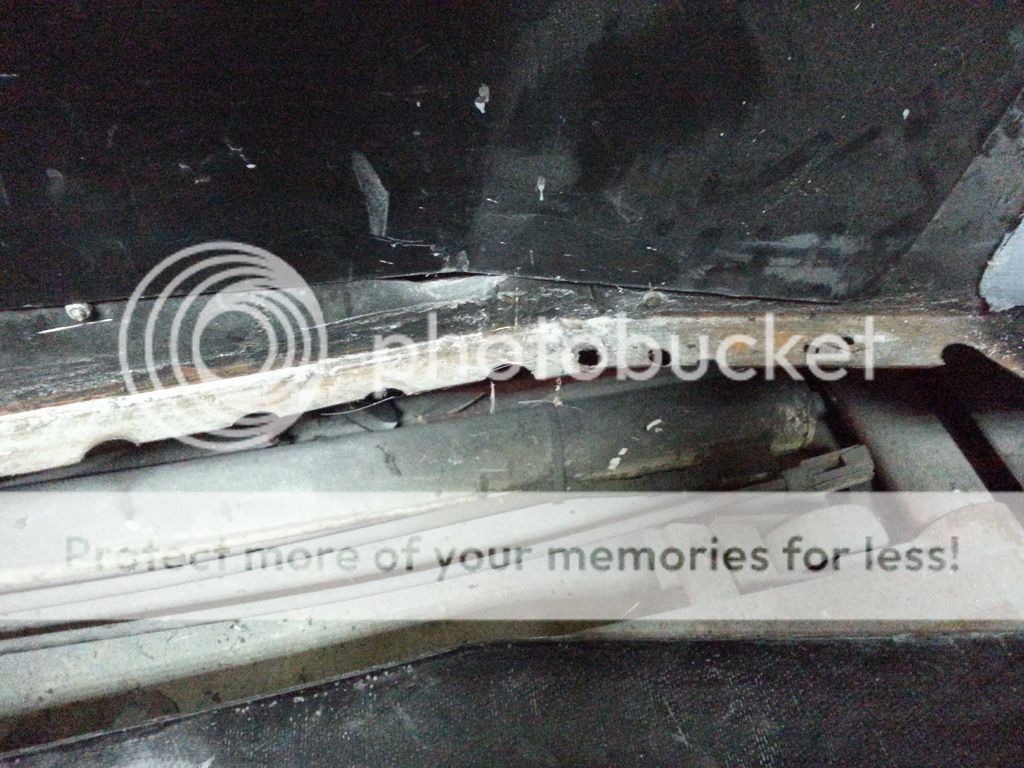

Not a lot happening at the moment. Trimming up floor support (removed 100gms  ), just needs a little more fettling to tidy it up. Decided to add a top of screen support. TIG welding is still crap but nothing that a grinder can't fix

), just needs a little more fettling to tidy it up. Decided to add a top of screen support. TIG welding is still crap but nothing that a grinder can't fix  I will leave the important welding to someone who knows what they are doing.

I will leave the important welding to someone who knows what they are doing.

Finished seat brackets today. You may be thinking, why have I painted them? Paint has a weight, but it also disguises the many imperfections and shoddy finish

They will be mostly hidden so I decided not to spend too much time on them. A total of 740gms removed. Not the 1Kg I was looking for but decided that stiffness was more important than lightness in this situation.

They will be mostly hidden so I decided not to spend too much time on them. A total of 740gms removed. Not the 1Kg I was looking for but decided that stiffness was more important than lightness in this situation.

Anyone who has built a car will appreciate that it's the little jobs that take up a lot of the time.

Two-part structural epoxy and 3 layers of carbon fibre should hold the blind nuts to the home made seat that is now relegated to the passenger side.

Trimming seat bracket support. These need to be as low as possible as I am somewhat lacking in headroom.

Two-part structural epoxy and 3 layers of carbon fibre should hold the blind nuts to the home made seat that is now relegated to the passenger side.

Trimming seat bracket support. These need to be as low as possible as I am somewhat lacking in headroom.

Martin from MJS Fabrications came over and finished off the parts of the roll cage that we couldn't get to originally due to the floor and sills being in the way. Also added a bar between the rear uprights, stiffening wedges in the top wishbones to compensate for the sections I took out to clear the damper pushrods and the driver's seat bracket supports. I can now crack on as the floors, which were holding up the installation of the dash and rear panels, can be installed.

T9 man

TC ModFather

Nice one Steve

Similar threads